We’ve all been there. That dreaded sound of a scoop scraping the bottom of an empty ice bin during the middle of a dinner rush. It’s a moment of pure panic for any restaurant or bar operator. Before you grab the phone to call for an emergency repair, just take a breath. A few quick, methodical checks can often solve the problem in minutes, no technician needed.

These first steps are simple and safe enough for any staff member to handle. The goal here is to rule out the easy stuff first, which can save you a world of time, stress, and money.

Your First Steps When The Ice Stops

Think of this as your initial triage. We're going to check the two most common culprits: power and water. It sounds almost too simple, but you'd be surprised how many expensive service calls end with a technician just plugging a machine back in.

Confirming Power and Water Supply

First up, power. Don't just glance at the machine's switch. Follow the power cord all the way to the outlet. Is it plugged in securely? Heavy-duty kitchen equipment, like a nearby commercial freezer or deep fryer, can vibrate just enough to jiggle a plug loose.

Next, make sure the outlet itself is working. The easiest way to do this is to unplug the ice maker and plug in something you know works, like a phone charger. If it doesn't light up, you've found your problem—it’s probably a tripped circuit breaker, not a dead ice machine.

With power confirmed, let's look at the water. Find the water line running into the back of your ice maker and trace it back to the shut-off valve, usually on a nearby wall or under a sink. Check that the valve is turned all the way to the "open" position. Even a partially closed valve can starve the machine of water, leaving you with no ice or just tiny, misshapen cubes. While you're back there, give the drain hose a quick look to make sure it isn't kinked or blocked.

Decoding Sights and Sounds

Your ice machine is often trying to tell you what's wrong. Most modern units have indicator lights. A steady green light is usually the "all good" signal, but a blinking red or yellow light means there’s a fault. Pull out the machine’s manual to see what those codes mean—it could be something as simple as a "clean me" alert.

Also, just listen. What do you hear? Or maybe more importantly, what don't you hear? If the machine is completely silent when it should be running, that points right back to a power problem. A constant clicking noise could be a relay switch struggling to kick on the compressor. On the other hand, if you hear a steady humming but not the usual sounds of water filling or ice dropping, you might be looking at a seized compressor or pump motor, which is a more serious issue.

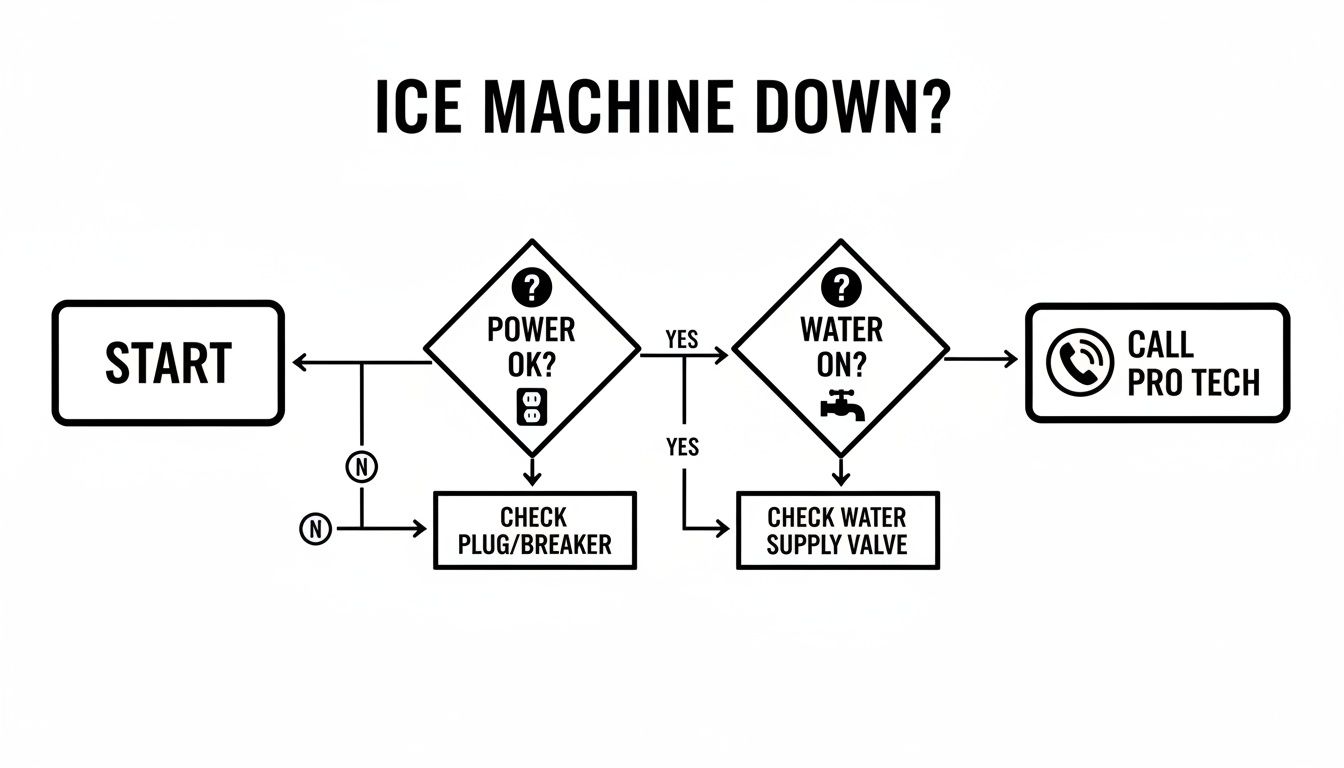

This simple flowchart is a great way to visualize these first few diagnostic steps.

Running through this quick decision tree ensures you’ve covered the most common and easily fixable problems before you decide it’s time to call in a pro.

To make it even easier, here's a quick-reference table you can post near your machine for staff to use.

Immediate Diagnostic Checklist

| Symptom | Immediate Check | Potential Simple Fix |

|---|---|---|

| Machine is completely off/silent | Power cord & outlet | Re-plug cord; reset circuit breaker |

| No ice is being made | Water supply valve & hose | Open valve fully; unkink the hose |

| "Clean" or "Service" light is on | Indicator panel | Run a cleaning cycle per manual |

| Small or misshapen ice cubes | Water filter & supply line | Replace clogged filter; check for low water pressure |

This checklist empowers your team to handle the basics, often getting you back up and running without any downtime.

The financial stakes are surprisingly high. Industry data shows that ice machine failures are one of the most expensive cold-side problems a restaurant can have. Each breakdown can cost an estimated $500 to $2,000 in lost revenue and emergency service fees. A 2021 analysis pegged the average repair cost for an ice machine at $708.44, a significant hit to already tight margins.

For a small Seattle coffee shop or pizzeria, a single outage can wipe out 1–2 percentage points of annual profit. That’s why running through these simple checks isn't just about convenience—it's about protecting your bottom line. You can find more insights about the operational costs of equipment failures from industry reports.

Solving Water Flow And Ice Quality Problems

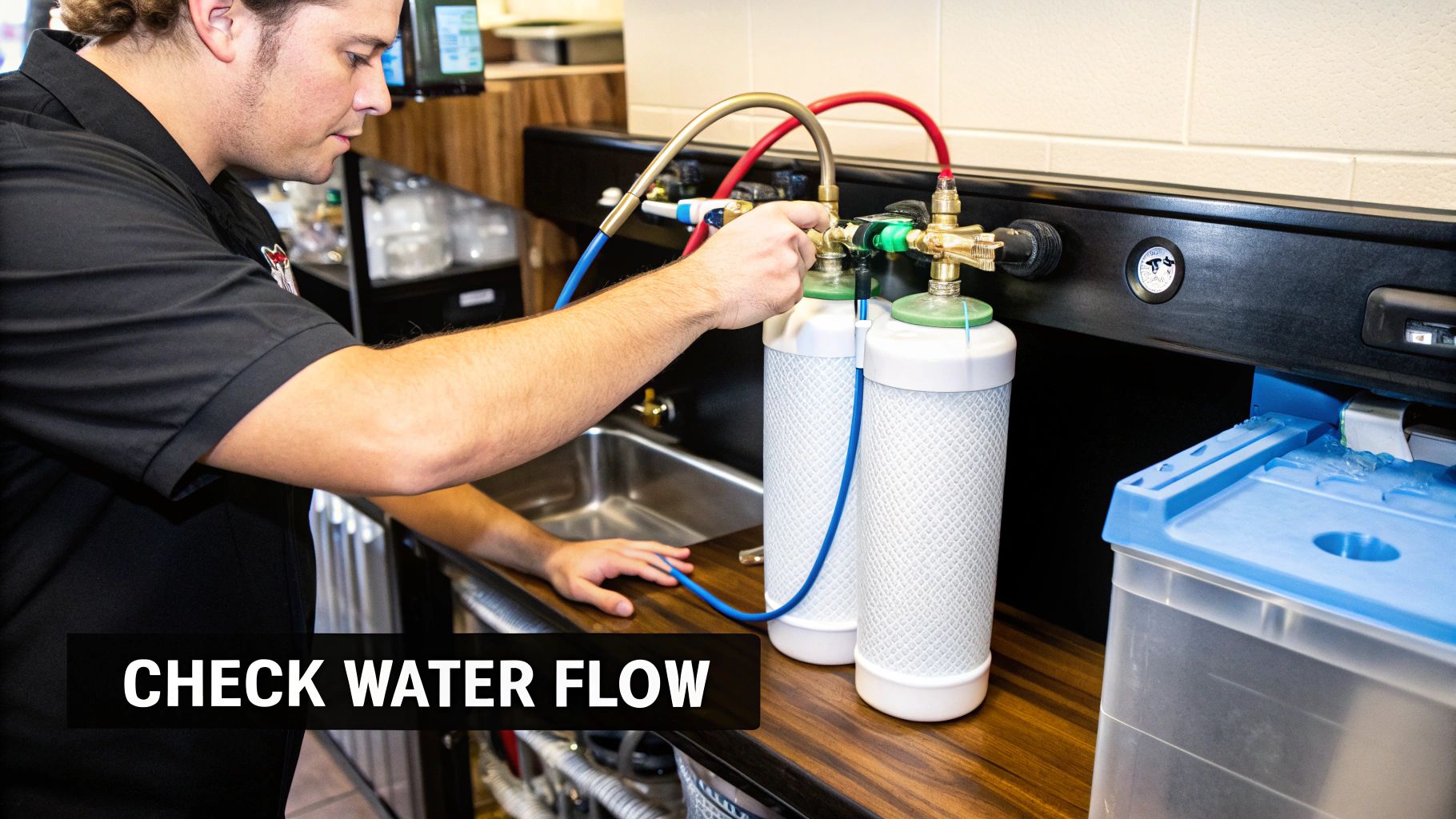

So, your ice machine has power, but the ice coming out is small, cloudy, or maybe there's no ice at all. Nine times out of ten, when I see this, the problem is somewhere in the water system. It's the most common point of failure, and the good news is, it's usually the easiest to fix. Before you start thinking about a major mechanical breakdown, let's walk through the most likely culprits connected to your water supply.

The first and most frequent offender is the water filter. Over time, filters get choked with sediment and minerals, which absolutely kills your water flow. Think of it like trying to drink a thick milkshake through a coffee stirrer—the machine just can’t pull enough water to make full, clear cubes. This restricted flow is the top reason for undersized, hollow, or weirdly shaped ice.

Inspecting Filters and Hoses

Your first move? Go check the water filter cartridge. Most people write the installation date on it. If it’s been more than six months, it's almost definitely time for a new one. Even if it's newer, really heavy sediment in your local water can clog a filter in just a couple of months.

While you’re back there, take a quick look at the water inlet hose running from the filter to your ice maker. A simple kink or something heavy leaning against the line can cut off the water supply just as effectively as a clogged filter. Make sure it has a clear, straight path.

Technicians I talk to say that water-related issues account for roughly 40% of all commercial ice maker service calls. It’s no surprise, since something as basic as a clogged filter can shut down production entirely.

Just checking your filters and hoses can often solve the problem right then and there, getting your ice production back up and running without a service call.

The Impact of Scale Buildup

If a fresh filter doesn't do the trick, the next thing to suspect is scale. Scale is that chalky, white buildup of hard minerals—mostly calcium and magnesium—left behind when water evaporates. It loves to coat the internal components, especially the evaporator plate where the water actually freezes into ice.

When scale builds up on the evaporator, it acts like an insulator. The machine has to work way harder to get cold enough, which leads to a bunch of problems:

- Longer Freeze Cycles: The machine runs and runs but makes less ice.

- Cloudy or Soft Ice: Those minerals get trapped inside the ice, making it look cloudy and melt faster in a drink.

- Component Strain: The compressor and other parts are forced into overtime, leading to more wear and a higher risk of a major failure down the road.

Field studies on ice equipment are pretty clear: scale buildup is the number one cause of reduced ice production. Just one proper descaling can restore 20–30% more output in many commercial units. This data really hammers home the point that troubleshooting often starts and ends with the water system. In one analysis, a whopping 60% of complete production failures were traced back to a clogged filter—a simple fix that could have prevented an emergency. You can read more about these common ice maker failure points and see just how vital water quality is for your machine.

Establishing a Filter Replacement Schedule

The best way to deal with these water problems is to prevent them in the first place. You need a non-negotiable filter replacement schedule. For most Seattle restaurants, bars, and coffee shops, every six months is a solid rule of thumb. Grab a permanent marker, write the date on the new filter, and set a recurring reminder on your calendar.

Keep in mind, not all filters are the same. The right one for you depends on your local water conditions and what kind of ice you need. A coffee shop that wants perfectly clear ice for its cold brew will need a better filtration system than a high-volume bar.

At Seattle Restaurant Equipment, we can help you find the right filters and descaling chemicals for your specific machine, whether it's a standard workhorse or a specialty unit sitting next to your other Seattle bar equipment or Seattle coffee shop refrigerators. Pro tip: always keep a spare filter on hand. It turns a potential day-long outage into a five-minute fix.

Diagnosing Mechanical And Electrical Faults

Alright, so you’ve checked the power and confirmed water is flowing, but the ice bin is still depressingly empty. Now we have to look deeper into the machine’s core components. This is where commercial ice maker troubleshooting can get a little intimidating, but you don’t need an engineering degree to spot when something is seriously wrong. A few key observations can point you right to the problem.

When an ice machine’s mechanical parts start to fail, the symptoms are often loud and clear. These signs usually signal something more serious than a simple clog, but knowing what they are can save a technician a ton of diagnostic time.

Common Mechanical Warning Signs

Is your ice machine running constantly but making little to no ice? That’s a classic sign of a struggling refrigeration system. The machine is desperately trying to get cold enough to make ice but just can't hit its target temperature. This could be anything from a filthy condenser coil to a failing compressor or even a refrigerant leak.

Another huge red flag is any kind of unusual noise. Your ice maker is supposed to make sounds—water filling, ice dropping—but you need to listen for anything new or alarming.

- Loud Grinding or Squealing: This almost always points to a motor in distress, like the condenser fan or the auger motor on a nugget machine. It could be worn-out bearings screaming for help, and you need to address it before the whole component seizes.

- Constant Buzzing or Humming: A low, steady hum without any other cycle sounds can mean a stuck water pump or a compressor that's trying to kick on but can't. That definitely requires a professional diagnosis.

- Banging During the Harvest Cycle: Hearing a loud clank or bang when the ice sheet should be dropping? You might have a bad harvest-assist mechanism or a problem with the solenoid that releases the ice.

These noises are your machine telling you a key part is under serious stress. Just like the motors in your commercial refrigerators or commercial freezers, these components will eventually fail if you ignore the warning signs.

Electrical Issues And When To Stop

Electrical problems are a different beast—they're often trickier and much more dangerous to diagnose without the right training. The most obvious sign of an electrical fault is an ice maker that keeps tripping the circuit breaker. If this happens, do not just keep flipping it back on. Breakers trip for a reason: to prevent overheating and a potential fire.

A constantly tripping breaker points to a short circuit or an overloaded component, like a compressor that’s on its last legs and drawing way too much power. This is your cue to unplug the machine and call for service. Another electrical symptom is a machine that’s completely dead even when you know the outlet has power. The culprit could be an internal fuse, a fried control board, or a bad power switch.

Safety is non-negotiable when dealing with electricity. Unless you are a qualified technician, your troubleshooting for electrical faults should stop at the circuit breaker. Opening up panels to inspect wiring or test components with a multimeter is a job for a professional.

Giving a technician specific information is a game-changer. Instead of just saying "the ice maker is broken," you can tell them, "It's tripping the breaker, and I heard a loud grinding noise right before it shut off." This directs them straight to the likely issue, saving you time and money on getting your Seattle restaurant equipment back online.

This same principle applies across your kitchen, from pizza prep tables to deep fryers. Understanding the link between an appliance's performance and its power consumption is key. For more on this, our guide on energy-efficient commercial refrigeration has some great insights. A sudden spike in energy use is often the very first sign that a mechanical or electrical part is about to fail.

Building A Proactive Maintenance Routine

Let's be honest, the best way to troubleshoot a commercial ice maker is to make sure it never breaks in the first place. You need to shift your thinking from panicked, last-minute repairs to a simple, proactive maintenance schedule. This one change is the single most effective thing you can do to guarantee a steady supply of ice for your Seattle coffee shop, Tacoma bar, or restaurant. This isn't about becoming a refrigeration technician; it's about consistent, basic care.

Think of it this way: a clean machine is a happy machine. Regular cleaning and sanitizing are completely non-negotiable. It's not just about performance; it's a critical food safety issue. Slime, scale, and mold are the top enemies of reliable ice production, clogging up internal parts and creating a truly unhealthy environment for the ice your customers consume.

Core Maintenance Tasks For Every Operator

So, what does this actually look like in practice? Let's break down the must-do tasks.

First up is descaling. This is the process of removing the hard, chalky mineral buildup (called scale) that coats the evaporator plate. When that plate is insulated by scale, your machine has to work much harder to produce less ice. How often you do this depends on your water hardness, but every six months is a solid starting point. You'll want to sanitize the machine at the same time to kill off any biofilm or bacteria. For a walkthrough on choosing the right products, check out our guide on ice machine cleaner and sanitizer.

Next, you have to clean the condenser coils. On most units, these look like the fins on a radiator, and their job is to get rid of heat from the refrigeration system. In a busy kitchen, they become magnets for grease, flour, and dust. This buildup acts like a blanket, trapping heat and forcing the compressor to overheat. The result? Ice production drops dramatically. A quick monthly brushing with a stiff bristle brush can make a massive difference.

Finally, give the bin sensors a check. Most ice makers use a sensor—either an infrared "eye" or a small curtain arm—to tell the machine when the storage bin is full. If these get dirty or bumped out of alignment, the machine might shut off way too early, leaving you with only half a bin of ice when you need it most. A quick wipe-down and visual check should be on your weekly to-do list.

Creating A Maintenance Log

To make sure these things actually happen, a simple maintenance log is your best friend. Just hang a clipboard next to the machine. This creates accountability and gives you a clear service history at a glance.

Your log should track:

- Date of Service: When was the work done?

- Task Completed: Was it a full descaling, coil cleaning, or just a filter change?

- Performed By: Which staff member took care of it?

- Next Due Date: When does this task need to be done again?

This little piece of paper is invaluable. It takes the guesswork out of maintenance and ensures important tasks don't get lost in the shuffle of a busy week. It's also a great tool for spotting recurring problems that might point to a bigger issue with your equipment.

Here's a straightforward schedule you can adapt for your own log.

Ice Maker Maintenance Schedule

| Task | Daily or Weekly | Monthly | Every 6 Months |

|---|---|---|---|

| Wipe Down Exterior | X | ||

| Check Bin Sensors | X | ||

| Inspect Water Filter | X | ||

| Clean Condenser Coils | X | ||

| Descale & Sanitize | X | ||

| Professional Service | (Recommended) |

Sticking to a schedule like this turns maintenance from a chore into a routine.

Here's something to think about: service data from refrigeration firms shows a clear link between routine care and reliability. Professionally maintained machines suffer 80% fewer emergency breakdowns compared to units that only get attention when they break. A well-kept machine can easily last toward the higher end of its typical 4–6 year lifespan, while a neglected one often fails much sooner.

This proactive mindset isn't just for your ice maker. It’s a best practice for all your essential kitchen equipment, from your main commercial refrigerators to the prep tables. A little time invested in maintenance pays off big time by preventing expensive downtime and getting the most life out of your gear.

When To Call A Pro And Find The Right Parts

So, you’ve checked the power, confirmed water is flowing, and even cleaned the condenser coils, but that ice maker is still just sitting there. Every restaurant operator who gets their hands dirty needs to know when to draw the line. While you can fix a lot of common hiccups yourself, some problems are big, flashing red lights telling you to call in a professional.

Pushing a machine with a serious internal issue can quickly turn a simple service call into a full-blown replacement. Knowing when to put down the wrench and pick up the phone is a skill that protects your staff, your investment, and your sanity. Certain symptoms are dead giveaways that the problem is buried deep in the machine's sealed or high-voltage systems—places where a DIY attempt is not just a bad idea, but a dangerous one.

Red Flags That Require A Technician

If you run into any of these situations, your very next move should be calling a qualified refrigeration tech. These aren't just maintenance tasks; they are signs of a major failure that requires specialized tools, training, and certifications to handle safely.

- Suspected Refrigerant Leaks: Notice a strange oily residue around the copper lines? Smell a faint chemical odor or hear a hissing sound you can't place? You could have a refrigerant leak. This is a hazardous material situation, and only a certified pro can handle it legally and safely.

- Compressor Failures: The compressor is the heart of your ice machine. If it starts making loud, clanking noises, feels scorching hot to the touch, or just refuses to turn on (even with power), it's probably on its last legs.

- Complex Electrical Faults: As we mentioned before, a machine that keeps tripping the circuit breaker is screaming for help. This almost always points to an electrical short or an overloaded component, which is a significant fire risk.

Do not, under any circumstances, try to fix these issues yourself. Working with refrigerants or high-voltage systems without the proper certification is incredibly dangerous and will absolutely void your equipment's warranty.

When you do make that call, be ready with the right info. Have the machine's make and model handy, and be prepared to describe exactly what it's doing—or not doing. Telling them "it runs but doesn't get cold" or "it started making a loud grinding noise last night" helps the technician diagnose the problem faster and show up with the right parts for the job.

Finding The Right Parts And When To Replace

Okay, so the technician has pinpointed a bad part, or maybe you've confidently diagnosed a simpler issue yourself, like a busted water pump or a faulty sensor. Now what? Your next hurdle is getting the right replacement part, and fast. You don't have time to sift through confusing online catalogs, hoping you're matching the right part number.

This is where Seattle Restaurant Equipment can be a real asset. We make it easy to find the exact components for the machines we sell. Whether you need water filters, pumps, bin sensors, or solenoids, we stock the parts to get you back up and running. Using genuine parts ensures a perfect fit and reliable performance, which you can't always say for a generic part you found online.

Of course, there comes a point when a repair just doesn't make financial sense. If your machine is getting up there in age and the repair estimate is more than 50% of what a new unit would cost, it’s probably time to start thinking about a replacement. This is especially true if you've had to call for service multiple times in the last year.

Sinking money into an old, inefficient machine can become a losing battle. Investing that money in a new, reliable ice maker is often the cheaper move in the long run. We can help you look at a whole range of modern, efficient options.

Whether you need a new bin for your current head unit or it's time for a completely new setup, a great place to start is by exploring our collection of commercial ice machines. Our team is here to help you weigh the costs and benefits so you can make the smartest decision for your budget and your business.

Frequently Asked Questions About Ice Maker Troubleshooting

Even the best-maintained ice machine will have a hiccup now and then. We field calls all the time from restaurant, bar, and coffee shop owners around Seattle facing the same handful of issues. Here are some quick answers to the most common problems we hear about, designed to help you solve the small stuff fast and get to know your equipment a little better.

Why Is My Ice Maker Making Small Or Cloudy Ice?

This is, without a doubt, the number one question we get. Nine times out of ten, the problem is water-related. The most common cause is a clogged water filter that’s restricting flow to the machine. Picture a kinked garden hose; if not enough water can get through, the machine can't form full, dense ice cubes.

Another huge culprit is mineral buildup—or scale—on the evaporator plate where the ice actually freezes. That scale acts like an insulator, preventing the plate from getting cold enough. The result? Soft, cloudy ice that melts way too fast in a customer's drink. First, try replacing your water filter. If that doesn't do the trick, your machine is probably telling you it’s overdue for a deep cleaning and descaling cycle.

My Machine Is Running But The Bin Is Empty. What's Wrong?

It’s a frustrating sound: you can hear the machine working hard, but the ice bin is bone dry. Before you panic, take a look at the ambient temperature around the unit. An ice maker is a piece of refrigeration equipment, just like your commercial refrigerators or under counter freezers, and they struggle in hot environments. If it's shoved into a hot corner of the kitchen with zero airflow, it simply can't get rid of heat efficiently enough to produce ice.

Next, check the condenser coil. If it's covered in a layer of grease and dust, it can't breathe. This is a classic problem in kitchens with deep fryers. Cleaning the coils is a maintenance task you can't skip. If the area is cool and the coils are clean, you might be facing a more serious issue like a refrigerant leak or a failing compressor. At that point, it’s best to call in a pro.

How Often Do I Need To Professionally Service My Ice Maker?

For most restaurants and bars in the Seattle area, we recommend a full professional service every six months. And that means more than just a quick wipe-down. A proper service visit should include a deep cleaning, sanitizing, descaling, and a complete mechanical inspection of all the components.

But your environment really matters. A pizzeria with flour dust constantly in the air or a brewery with active yeast might need to bump that schedule up to every three or four months. High-grease kitchens also see slime and mold build up much faster. Think of regular professional service as an investment that prevents costly emergencies and adds years to your machine’s life.

A good rule of thumb is the 50% rule. If a repair is going to cost more than half the price of a new, comparable machine, it's almost always smarter to replace it.

This simple calculation keeps you from pouring good money into a machine that’s already on its last legs.

Should I Repair My Old Ice Maker Or Replace It?

This is the big question every operator faces eventually. Beyond the 50% rule, you have to look at the machine's age and its recent repair history. If your ice maker is more than seven years old and you've had to call for service multiple times in the past year, it's giving you a pretty clear signal.

A new unit from Seattle Restaurant Equipment isn't just about reliability; it’s also going to be significantly more energy-efficient, which helps your utility bills. The hidden costs of an old machine—constant repairs, spoiled product, the stress of last-minute ice runs—add up fast. Putting that money toward a new machine with a fresh warranty is often the best financial move for your business. The same thinking applies to other workhorses in your kitchen, like sandwich prep tables and commercial freezers.

Whether you're working through a minor glitch, grabbing more cleaning supplies, or deciding it's time for an upgrade, Seattle Restaurant Equipment has the gear and the expertise to keep your kitchen humming.

Explore our full range of commercial kitchen equipment today.