Before you even think about firing up a range or dropping a basket in the fryer, we need to talk about the real foundation of your kitchen: solid cold storage and smart prep stations.

This isn't just about buying a fridge. It's about setting up the backbone of your entire operation. Getting this right from the start ensures your ingredients stay fresh, your team works efficiently, and you stay on the right side of the health inspector. For any food business in Washington, from a food truck in Spokane to a fine-dining spot in Seattle, this is where your checklist truly begins.

Laying the Groundwork: Cold Storage and Prep Stations

Think about it—the needs of a cozy Bellevue coffee shop are completely different from a high-volume Tacoma pizzeria. The coffee shop might just need a compact undercounter refrigerator for milks and creams, keeping everything within easy reach for the barista. The pizzeria, on the other hand, absolutely requires a heavy-duty pizza prep table with refrigerated rails to keep toppings perfectly chilled and organized during the dinner rush.

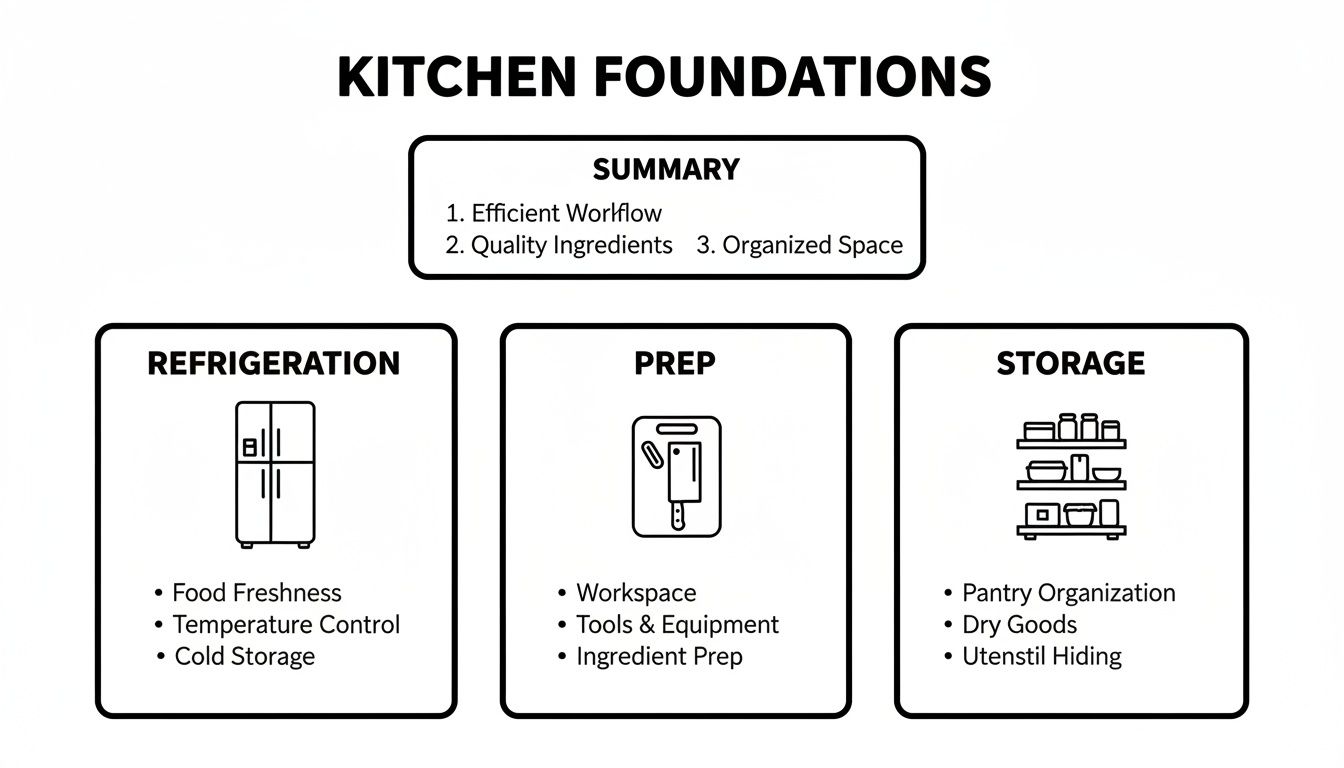

This simple diagram breaks down how these foundational pieces work together.

As you can see, a great kitchen isn't just a collection of equipment; it's a system. The flow between your refrigeration, prep areas, and storage is what creates a seamless, efficient workspace.

Choosing Your Core Refrigeration Units

Picking the right commercial refrigeration is more nuanced than just finding something that fits. You have to think about purpose. A standard reach-in commercial refrigerator is perfect for bulk storage in the back, but a sleek Seattle coffee shop refrigerator up front is what sells drinks and grab-and-go items.

The same goes for freezers. While a reach-in commercial freezer is a staple for almost any kitchen, specialized units can be a game-changer. An under counter freezer tucked into a busy prep line, for instance, can save your chefs countless steps and precious seconds during a chaotic service.

Investing in quality refrigeration isn't just about storage—it's about protecting your biggest asset: your inventory. Food cost is a massive expense, and proper temperature control is your first line of defense against spoilage and wasted money.

The Importance of Specialized Prep Tables

Prep tables are where your menu comes to life. A well-designed sandwich prep table combines a durable cutting board surface with refrigerated compartments below, allowing your staff to build orders at lightning speed without ever leaving their station.

This focus on efficiency is a big deal in the foodservice world. In fact, kitchen-purpose equipment—including refrigerators, freezers, and prep tables—accounted for the largest revenue share at 36.9% across North America. It’s clear that smart operators are prioritizing gear that reduces waste and boosts safety. You can see more on that trend over at Grandview Research.

For pizzerias, a dedicated pizza prep table isn't a luxury; it's essential. These units are built with wide marble or stainless steel surfaces for working dough and have refrigerated rails to keep cheese, sauce, and toppings at safe, consistent temperatures.

Integrating Cooking and Cooling

Even your hot line depends on cold storage. A strategically placed under counter refrigerator by the grill station holding prepped burger patties and cheese slices is a must. A small freezer right next to the deep fryers for fries or onion rings is just as critical. Integrating your hot and cold equipment this way is the secret to a fluid, productive kitchen that just works.

Here’s a quick-reference table to help you nail down the essentials for your specific business.

Essential Cold Storage and Prep Equipment by Business Type

| Business Type | Must-Have Refrigeration | Essential Prep Tables | Key Considerations |

|---|---|---|---|

| Full-Service Restaurant | Walk-in Cooler/Freezer, Multiple Reach-Ins | Stainless Steel Work Tables, Salad/Sandwich Prep Table | High volume demands robust, separate storage for raw and cooked items. |

| Food Truck | Undercounter Fridge/Freezer, Small Reach-In | Compact Sandwich Prep Table, Stainless Steel Countertop | Space is premium. Every unit must be compact, durable, and energy-efficient. |

| Coffee Shop / Bakery | Undercounter Fridge, Glass-Door Merchandiser | Stainless Steel Work Table, Baker's Table (with wood top) | Display is key for grab-and-go. Baker's tables are better for dough work. |

| Pizzeria | Walk-in Cooler, Reach-In Freezer, Dough Retarder | Dedicated Pizza Prep Table with refrigerated rails | Temperature control for dough is crucial. Prep table must be wide enough. |

| Catering Business | Reach-In Cooler/Freezer, Transport Holding Cabs | Large Stainless Steel Work Tables (often portable) | Portability and temperature maintenance during transport are top priorities. |

Ultimately, getting this foundation right means investing in reliable, durable equipment that's built for your specific menu and workflow. To get a better sense of what's out there, check out our guide on the best commercial refrigerators for your business. Smart choices here will pay off for years to come.

Building Your Hot Line Core Cooking Equipment

The hot line is the engine room of your kitchen—it's where the magic happens and your menu comes to life for every single customer. Picking out the right core cooking equipment isn't just about filling a space. It’s a serious investment in the gear that will define your kitchen’s speed, consistency, and ability to handle the dinner rush.

A well-equipped hot line is a massive advantage. Picture a food truck owner in Kent trying to decide between a gas and an electric deep fryer. That choice comes down entirely to their mobile power setup and menu. In the same way, a new restaurant in a cramped Spokane storefront might go for a multi-burner commercial range with a built-in oven to make every square inch count.

Selecting Your Primary Cooking Tools

The foundation of any hot line is built on a few essential pieces. The choices you make here should be a direct reflection of what's on your menu. There's no single perfect setup, but most successful kitchens rely on these versatile workhorses.

- Commercial Ranges: The absolute classic of any cook line, a commercial range gives you open burners on top with an oven underneath. You'll need to think about how many burners you need for your busiest service and whether a standard or convection oven base will work best for your roasting and baking.

- Deep Fryers: A must-have for everything from crispy fries to fried chicken. Whether you go with a gas or electric model will depend on your utility hookups and how fast you need the oil to recover its temperature. Gas fryers tend to heat up quicker, which is a huge plus for high-volume spots.

- Griddles and Charbroilers: A flat-top griddle is your best friend for breakfast items, burgers, and getting that perfect sear on fish. A charbroiler, on the other hand, gives you those iconic grill marks and smoky flavor that people crave. A lot of kitchens find they need both.

Investing in solid cooking equipment is part of a bigger picture. The global market for this gear is expected to hit USD 26.5 billion by 2035, growing at a steady 7.1% each year as more restaurants open up. Full-service restaurants and hotels make up 47.8% of this market, which tells you just how much high-volume kitchens value durable, high-performance equipment. You can see more on this growing demand over at Future Market Insights.

The Power of Specialized Ovens

While the oven in your range is a great start, adding a dedicated commercial oven can seriously expand what you can offer and make your food more consistent. Convection ovens, for instance, use fans to move hot air around, which means food cooks faster and more evenly.

This is a complete game-changer for bakeries, caterers, or any restaurant that needs perfectly roasted meats and vegetables. Those faster cook times can also give your kitchen a major output boost during a crazy dinner service. For a closer look at how they work, you can learn more by comparing convection vs regular ovens in our detailed guide.

A key takeaway for your commercial kitchen equipment checklist is to choose equipment that can handle your peak volume without faltering. The last thing you want is a range that can't keep all burners hot or a fryer that struggles to recover temperature, slowing down your entire service.

Making Smart Choices for Your Space

The layout of your kitchen in Seattle or Bellevue has a huge impact on what equipment you can even consider. Before you buy anything, get in there with a tape measure. Pay close attention to where your ventilation hoods and utility hookups are.

Look for equipment that can pull double duty to save space and cash. A combi oven, for example, can steam, roast, and bake all in one unit. Similarly, a range that comes with a griddle top means you don't have to buy a separate piece of equipment.

Ultimately, you want to build a hot line that helps your chefs shine, not one that holds them back. By focusing on versatile, reliable, and correctly sized equipment, you're setting your kitchen up for success. That initial investment in core pieces will pay you back with every perfectly cooked dish that goes out to a happy customer.

Finding Your Niche with Specialty Equipment

Sure, the big-ticket items like your hot line and walk-in cooler are the backbone of any kitchen. But let's be honest—it's the specialty gear that really sets you apart and brings your concept to life. A generic commercial kitchen equipment checklist is a good start, but it won't give you the edge you need. To really carve out your niche, you have to invest in the tools that make your specific menu sing.

For food businesses across Washington, this is about getting granular. Think about that packed Seattle bar on a Friday night—its success depends entirely on speed and perfectly chilled drinks. Or that cozy Everett coffee shop where a beautifully lit bakery case is practically a silent salesperson, moving pastries all day long. These are the thoughtful investments that take an operation from just another option to a go-to spot.

Equipping a High-Volume Seattle Bar

The soul of a great bar is its workflow. And that flow is all about the equipment. Your Seattle bar equipment isn't just a collection of machines; it's a finely tuned system built for churning out drinks, fast. When you're three-deep at the bar, the last thing your team needs is to be running around.

This is where specialized underbar units become your best friends.

- Under Counter Refrigerators: These are non-negotiable. They keep your bottled beers, white wines, and mixers perfectly chilled, right where the bartender needs them.

- Under Counter Freezers: A must-have for stashing extra ice or chilling down specialty glassware for that flawless cocktail presentation.

- Glass Chillers and Frosters: This little touch makes a huge impact. Serving a local craft beer in a frosty mug is a detail that customers absolutely notice and love.

Beyond the cold stuff, a smart setup includes multi-compartment sinks for the classic wash-rinse-sanitize routine and dedicated ice bins. It's not just about making life easier for your bartenders; it's about pumping out more drinks per hour and keeping your customers happy.

Powering Your Everett Coffee Shop

In the coffee world, vibe is everything. And while your espresso machine is the star of the show, the supporting cast of Seattle coffee shop refrigerators and display cases are what really drive your profits.

A rookie mistake is grabbing any old standard refrigerator. A glass-door merchandiser placed right by the register, however, is a master of the impulse buy, perfect for showcasing bottled juices and cold brews. In the same way, a gorgeous, well-lit bakery display case transforms a simple croissant into an irresistible treat.

When you're picking out refrigeration, you need to think about both function and form. Your equipment shouldn't just keep things fresh—it should add to the welcoming vibe that makes people want to hang out and open their wallets.

The right units keep your milk perfectly foamy for lattes and your scones looking fresh-out-of-the-oven delicious. For a complete rundown of everything you’ll need, check out our full coffee shop equipment checklist.

The Workhorses for Pizzerias and Delis

Some businesses are built around one monster piece of equipment. For pizzerias and delis, that workhorse is the prep table. These are so much more than just stainless steel surfaces; they’re fully integrated workstations designed for pure efficiency.

A pizza prep table is an absolute game-changer. You get a wide surface—often stone or marble—for stretching dough, plus refrigerated rails up top holding all your toppings. With a setup like this, one person can build pizzas at a dizzying pace, keeping things consistent and quick, even during the dinner rush.

Similarly, no deli or sandwich shop can survive without a proper sandwich prep table. It’s an all-in-one station with a cutting board surface and chilled wells for all your meats, cheeses, and veggies. Underneath, commercial refrigerators or commercial freezers hold your bulk inventory. This design radically slashes the time it takes to build an order, which directly boosts customer satisfaction and how many people you can serve. These specialized units, along with heavy-duty deep fryers for sides, are the real engines behind any focused, high-volume menu.

The Unsung Heroes: Storage and Sanitation Gear

Your flashy six-burner range and gleaming walk-in cooler might get all the glory, but they’re useless without the right support system. The real workhorses of any high-functioning kitchen are the unsung heroes: smart storage and tough sanitation gear. This is the stuff that keeps your operation organized, clean, and out of trouble with the health inspector.

Without a solid plan for storage and warewashing, even the best chefs will find themselves drowning in chaos. Investing in quality stainless steel tables, proper shelving, and the right dishwasher isn't just about passing inspections. It’s about building a smooth workflow that saves you serious time and money.

Smart Storage Solutions for Every Corner

Good storage is more than just finding a place to stash your inventory. It’s a strategy. It’s about keeping food safe, making the most of your square footage, and making prep a whole lot faster.

- Commercial Wire Shelving: This is your go-to for any dry storage area. The open-wire design is great for air circulation, which helps keep dust down and lets you see what you have with a quick glance. No more "lost" cases of canned tomatoes in the back.

- Dunnage Racks: An absolute must for your walk-in coolers and freezers. Health codes demand that all food is stored at least six inches off the floor. These low, heavy-duty racks are perfect for holding bulk items like sacks of flour, boxes of produce, or tubs of sauce.

For any kitchen in Seattle, from a small cafe to a fine dining spot, getting your storage right is fundamental. It directly impacts how clean, organized, and code-compliant you can be.

The Critical Role of Warewashing

Nothing stops a busy service dead in its tracks like a mountain of dirty dishes. The warewashing system you choose has to match your volume and your space. A cozy bar in Renton, for example, can probably get by just fine with a compact undercounter dishwasher for glassware and small plates. It’s efficient, tucks away neatly, and keeps the bar running smoothly.

On the other hand, a massive catering operation or a slammed downtown restaurant needs some serious firepower. A high-temperature conveyor dishwasher can blast through hundreds of racks an hour, making sure you never run out of clean plates, pans, or utensils, even on a crazy Saturday night.

A well-planned sanitation station is completely non-negotiable. Think of it as an investment in food safety and operational sanity. The cost of a foodborne illness outbreak—in fines, legal fees, and a ruined reputation—is infinitely higher than the price of a good dish machine.

Durable Surfaces and Sanitation Stations

Every single surface in your kitchen needs to be tough, non-porous, and a breeze to sanitize. There’s a reason stainless steel is the industry standard. Stainless steel work tables can take a beating day in and day out, from heavy chopping to hot pans, and still clean up perfectly.

Beyond the tables, you need a complete sanitation setup. This means:

- Three-Compartment Sinks: These are required for manually washing, rinsing, and sanitizing all your large pots, pans, and utensils that won't fit in the dishwasher.

- Handwashing Stations: You need dedicated sinks, complete with soap and paper towels, just for handwashing. They have to be strategically placed throughout the kitchen—and kept separate from any food prep or dishwashing areas—to meet health codes.

These pieces are the bedrock of a safe kitchen. They aren't just items to check off a list; they are the tools you and your team will use every single day to protect your customers and your business.

Funding and Sourcing Your Kitchen Equipment

Alright, you've got your list of essential gear. This is where the dream starts to feel real, and honestly, where it can get a little intimidating. Now we’re talking about how to actually pay for and get that equipment into your Washington restaurant.

Don't panic. A smart approach here can make all the difference, helping you get everything you need without blowing your startup cash all at once. The goal isn't just to buy stuff—it's to make sharp financial moves that set you up for success down the road. It’s about more than the sticker price; you have to think about energy costs, how reliable a unit is, and what happens if it breaks.

Creating a Practical Equipment Budget

First thing's first: let's get that commercial kitchen equipment checklist organized. Not everything is a "day one" purchase. I always tell new owners to think in tiers.

-

Tier 1: The Must-Haves. You absolutely cannot open without these. We’re talking your main commercial refrigerators, commercial freezers, and the heart of your hot line, like deep fryers and ranges. If you're a deli, your sandwich prep table is in this tier. A pizzeria? That pizza prep table is non-negotiable.

-

Tier 2: The Should-Haves. This is the gear that will make your life a whole lot easier and your kitchen more efficient, but you could technically survive without it for a week or two. Maybe it’s an extra under counter refrigerator for a prep station or some specific Seattle bar equipment to speed up drink orders.

-

Tier 3: The Nice-to-Haves. This is your wish list. The stuff you can add once the cash starts flowing. It might be a fancy display case or a specialized piece of cooking tech you’ve been eyeing.

Breaking it down this way lets you put your initial money where it matters most—on the equipment that will actually start making you money.

Exploring Smart Financing Options

A lot of new restaurateurs think they have to buy every single piece of equipment with cash. That’s a surefire way to drain your bank account before you even serve your first customer. There are financing programs out there designed specifically for businesses like yours, whether you’re opening a food truck or a full-service restaurant.

Don't let a tight initial budget force you into buying unreliable used equipment that comes with no warranty. Financing new, warrantied equipment often provides a much lower total cost of ownership and prevents the costly downtime that comes with unexpected breakdowns.

Financing lets you spread out the cost, keeping your cash free for all the other things you need to pay for, like payroll, marketing, and your first big food order. For many new businesses, that flexibility is what gets them through the tough first year.

Sourcing Your Equipment with a Local Partner

Okay, budget is set and financing is lined up. Now, where do you get the actual equipment? My advice is always to work with a local Washington supplier like Seattle Restaurant Equipment. You get real, personalized support and fast, free local delivery to places like Seattle, Tacoma, Bellevue, and Spokane, which is a huge deal.

Versatility in your cooking line—things like gas or electric fryers and griddles—is key. The demand for this type of equipment is booming, with North America making up 32% of the market and growing at 4.0%. You can read more about it over at The Business Research Company. This just shows how important it is for bar or pizzeria owners to find a supplier who gets them solid, warrantied gear at a good price, without long shipping delays.

When you work with a local partner who knows the scene, you get more than just a delivery. You get a resource. Someone who can help you pick the right under counter freezer for a tiny kitchen or choose the best Seattle coffee shop refrigerators to show off your pastries. With clear pricing, no sales commissions, and good warranties, you can be sure you're getting real value and getting your kitchen up and running without the usual headaches.

Common Kitchen Equipment Questions Answered

Pulling together a commercial kitchen is a massive project, and naturally, you’re going to have questions. It's easy to get overwhelmed trying to make the right call on everything from your budget to long-term equipment care. We've pulled together some of the most common questions we hear from Washington restaurant owners to give you straight, clear answers.

These insights come from years of helping businesses—from bustling Seattle bars to neighborhood Spokane pizzerias—get the gear they need to hit the ground running. Let's dig in.

Should I Buy New or Used Equipment?

This is the big one, the first question almost every new operator asks. Used equipment can look like a steal upfront, but it's a huge gamble. You almost never get a warranty, you have no idea what its service history looks like, and a sudden breakdown could cost you thousands in lost sales and emergency repair bills.

New equipment, on the other hand, comes with the manufacturer's warranty, meets the latest energy-efficiency standards, and gives you the peace of mind that it’s going to work reliably right out of the box. Honestly, financing new gear often makes more financial sense in the long run than pouring money into constant repairs for a mystery machine.

How Do I Know When to Repair or Replace a Unit?

This is a constant battle for any kitchen manager. Do you patch up the old machine one more time or invest in something new? A great rule of thumb we use is the 20% rule. If a repair for a core piece of equipment, like a commercial refrigerator or a deep fryer, is going to cost more than 20% of a brand-new replacement, it's usually smarter to replace it.

Here are a few other things to think about:

- Constant Breakdowns: Is this unit always on the fritz? If it's constantly out of service, its unreliability is costing you a lot more than just the repair bill.

- Age & Efficiency: Most equipment, especially refrigeration, has an expected lifespan of about 10-15 years. Older units are energy hogs. A new, efficient model can make a serious dent in your monthly utility bills.

- Safety Issues: This one is non-negotiable. If a piece of equipment has any kind of persistent safety problem, replace it immediately. No exceptions.

What are the Most Common Maintenance Tasks?

Preventative maintenance is the secret weapon for getting the most out of your investment. This isn't just about cleaning—it's about proactive care that stops major breakdowns before they happen.

Regular maintenance is your best defense against unexpected downtime. Simple daily and weekly checks on your essential equipment—from commercial freezers to sandwich prep tables—can extend its life by years and save you from costly emergency service calls.

Here are a few key tasks you should have on a regular schedule:

- Clean Your Coils: The condenser coils on your refrigeration units (like under counter refrigerators and those hard-working Seattle coffee shop refrigerators) need to be cleaned monthly. This helps them release heat properly and run efficiently.

- Check Your Gaskets: Inspect the door seals on all your cold storage, from a big reach-in to a small under counter freezer. A cracked or torn seal makes the unit work harder and bleeds energy.

- Calibrate Thermostats: You should be regularly checking the temperatures in your ovens and fryers. Accurate temps are critical for both food safety and consistent quality.

How Much Should I Budget for Equipment?

There’s no magic number here—it all comes down to your concept. A food truck has completely different needs than a full-service restaurant. The smartest way to approach this is to create a tiered list.

Start by prioritizing the absolute essentials you need to open your doors. This means your core refrigeration, your main cooking line, and a critical prep station like a pizza prep table. Then, create a "should-have" list and a "nice-to-have" wish list for things you can buy once you're profitable. Working with a supplier who offers transparent pricing and financing options helps you get high-quality, reliable gear without wiping out your startup capital.

Ready to build a kitchen that can handle anything? Seattle Restaurant Equipment offers a massive selection of new, warrantied gear with fast, free delivery across Washington. From reliable cold storage to a high-performance hot line, we make it simple and affordable to get the equipment you need.

Explore our full inventory and find the perfect solutions for your business at https://seattlerestaurantequipment.com.