In most commercial kitchens, a convection oven’s fan-driven system keeps heat circulating around trays, cutting cook times by about 25% and smoothing out hot spots. On the other hand, a regular oven relies on fixed heating elements for a simple, dependable bake cycle.

Key Differences Between Convection And Regular Ovens

- Cooking speed often sees a 10–25% faster turnaround in convection models compared to static bake cycles.

- Utility bills can shrink by up to 20%, thanks to lower temps and shorter runtimes.

- Capacity jumps when you stack trays—convection’s airflow keeps temperatures even across multiple racks.

“Convection delivers consistent results in high-volume kitchens, while regular ovens excel in simplicity and reliability,” says Chef Larson of Pike Place Café.

| Metric | Convection Oven | Regular Oven |

|---|---|---|

| Cooking Speed | 10–25% faster | Standard cycle time |

| Energy Use | Up to 20% lower | Baseline consumption |

| Capacity | Multi-rack uniform | Hot spots on racks |

For Seattle restaurateurs, the right oven affects more than just bake time. You’ll align ovens with commercial refrigerators and freezers, under-counter units, sandwich and pizza prep tables, bar equipment, coffee shop refrigerators, and deep fryers to keep every station humming.

Benefits For Different Stations

- Pair convection ovens with commercial refrigerators and under-counter freezers so ingredients stay fresh and within arm’s reach.

- Match regular ovens with pizza prep tables and sandwich prep tables for predictable dough proofing, toasting, and bake cycles.

- Integrate ovens adjacent to bar equipment for quick garnish toasting and warm glassware service.

- Use convection units beside deep fryers to jump straight from fryer to oven without a cooldown lag.

- Slot a regular oven near coffee shop refrigerators when you need slow, gentle reheats that preserve product integrity.

- Align ovens with commercial freezers to streamline thaw-to-bake workflows.

This snapshot shows how each oven type slots into its own niche. In the following sections, we’ll dig into airflow mechanics, performance benchmarks, and practical maintenance tips.

For Seattle Restaurant Equipment customers, these insights guide smarter station layouts and smoother workflows. Picking the right oven can trim energy costs, boost throughput, and streamline compliance with local codes.

Whether you’re pairing with sandwich prep tables, pizza prep tables, under-counter refrigerators/freezers, bar equipment, or deep fryers, this guide will help Seattle kitchens run at peak efficiency.

Get ready.

Understanding Oven Technologies

Convection and conventional ovens both play starring roles in busy commercial kitchens—but they achieve heat in very different ways.

In a convection oven, fan-driven airflow circulates hot air around the cooking chamber. That constant movement cuts down on cold spots and shaves minutes off each cooking cycle.

Conventional—or static—ovens, on the other hand, rely on fixed heating elements at the top and bottom. The result is steady radiant heat, but you’ll often have to shuffle pans to dodge those inevitable hot and cool pockets.

Key Factors at a Glance:

- Chamber Materials: Stainless steel vs. ceramic or stone-lined decks

- Insulation Thickness: Heavier insulation holds heat longer but adds weight

- Airflow Patterns: Circulating air vs. natural convection

These mechanical differences ripple through your kitchen layout. Near sandwich prep tables, pizza stations, or bar equipment—where timing can make or break service—you’ll see the impact in real time. For instance, slotting a convection oven beside a coffee shop refrigerator can speed up morning pastry re-runs by several minutes, keeping customers happier and lines moving.

Airflow Paths And Temperature Zones

Cross-sectional schematics make it clear: convection fans push air in a loop, locking in a uniform temperature from rack to rack. Static ovens? You get zones that hug the element, which means rotating pans to chase that even bake.

| Feature | Convection Oven | Static Oven |

|---|---|---|

| Heating Method | Fan-driven circulation | Top/bottom radiant elements |

| Rack Capacity | 3–5 racks with consistent results | Best performance on a single rack |

| Hot Spot Management | Minimal—airflow evens out temperatures | Requires manual pan rotation |

Insight: When you need to batch-bake multiple trays—think hotel brunch or catering orders—a convection oven can boost throughput by up to 30 percent versus a conventional unit.

Cost factors span from energy consumption to installation complexity—especially if you’re integrating with display cases or custom stainless-steel stations from Seattle Restaurant Equipment.

Global sales data underline the shift: the convection oven market jumped from USD 4.1 billion in the early 2010s to USD 5.8 billion by the mid-2020s, driven by demand across North America, Europe and Asia-Pacific.

Explore the latest convection oven market findings

For a custom fit next to your prep line, check out our commercial convection ovens in Seattle.

Integration With Kitchen Stations

Matching ovens to adjacent stations can shave seconds—or minutes—off each dish:

- Sandwich Prep Tables: Convection ovens sync bake cycles with ingredient staging, avoiding bottlenecks.

- Pizza Prep Tables: Static ovens keep dough proofed at a steady heat, giving bakers a predictable canvas.

- Commercial Refrigerators & Freezers: Position ovens near full-size fridges/freezers to cut ingredient fetching time.

- Bar Equipment: Placing ovens near bar stations helps toast garnishes and warm glassware efficiently.

- Coffee Shop Refrigerators & Under-Counter Freezers: Cutting transit time for quick reheat cycles keeps morning rush lines moving.

Visual call-outs in your training manuals—highlighting hot zones and cool zones—help staff dial in consistency, whether they’re checking temperatures or rotating racks.

Staff retraining is crucial when swapping oven types. A quick workshop on airflow checks and rotation routines ensures every batch meets your kitchen’s exacting standards.

Convection Strengths:

- Uniform browning across multiple racks

- Faster pre-heat times

- Stable temperatures during long runs

Static Oven Strengths:

- Simple dial controls

- Predictable radiant heat signature

- Lower maintenance demands

Understanding these mechanical foundations equips you to choose the right oven for your operation. Next up, we’ll break down cooking performance and timing nuances to fine-tune your menu success. Stay tuned for detailed guidance.

Comparing Cooking Performance And Timing

When balancing speed and consistency in a busy kitchen, the differences in how convection and regular ovens handle heat can make or break your service flow.

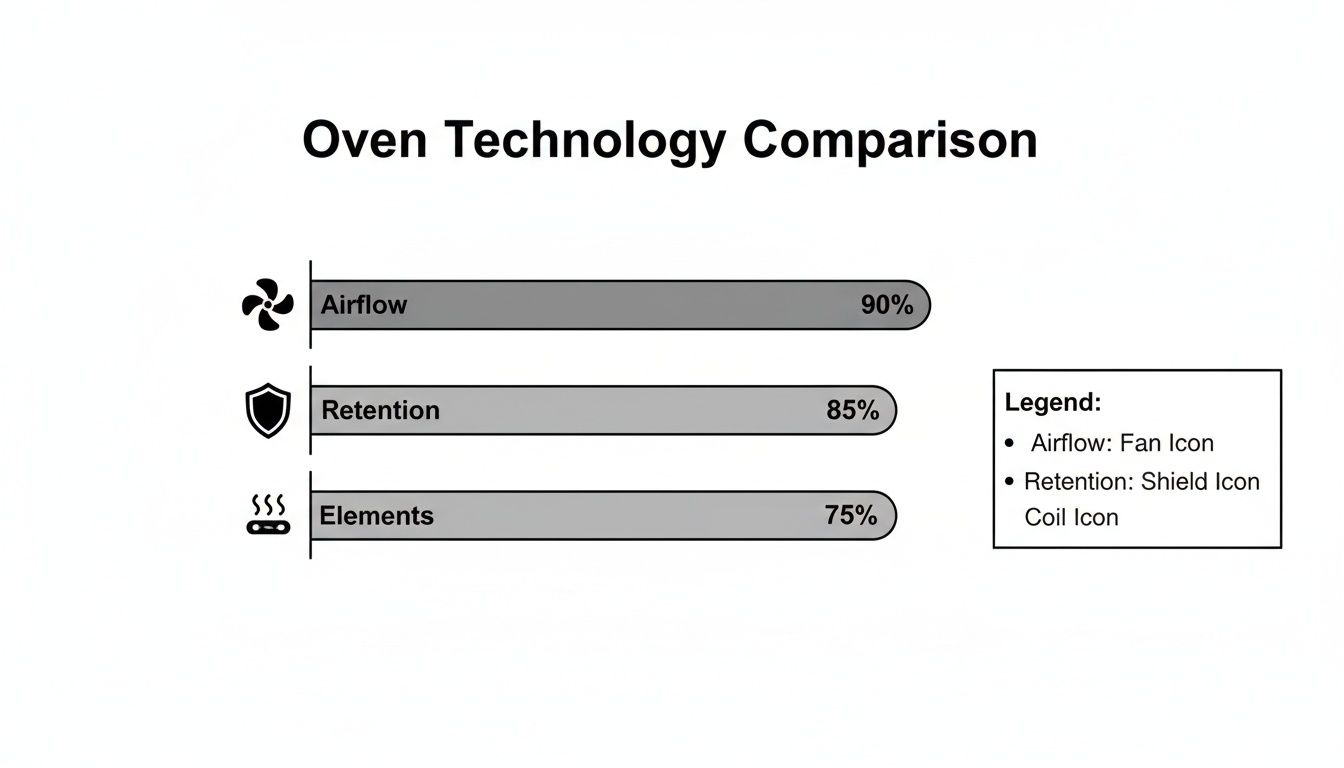

This diagram shows the fan mounted at the rear, circulating air evenly across multiple racks. The result? Fewer hot spots and reliable results from top to bottom.

Cooking Time Differences

Professional bakeries in Seattle note that a convection oven can wrap up cookie batches 25% faster than a standard deck, freeing space for pizzas, sandwiches, or bar snacks.

“Swapping to a convection deck shaved off minutes on our focaccia bakes, and crusts stay crisp thanks to the airflow,” says Chef Ramirez of Capitol Hill Pizzeria.

Below is a side-by-side look at cooking durations and temperature settings in these ovens.

Cooking Time And Temperature Comparison

| Metric | Convection Oven | Regular Oven |

|---|---|---|

| Cooking Time Reduction | 10–25% faster | Baseline cycle times |

| Temperature Setting | 10–20°C lower | Standard manufacturer specs |

| Rack Capacity | Up to 4–6 trays with uniform results | Single-tray loading |

| Throughput Impact | +30% batches/day | Typical daily throughput |

From these figures, it’s clear that convection models push more trays through without sacrificing bake quality.

Temperature Settings And Energy Insights

Running at 10–20°C lower than conventional ovens, convection units often shave around 15% off monthly energy bills. A local café reported exactly that after switching to a countertop convection model, aligning with data from the Future Market Insights convection oven energy report.

Lower setpoints mean shorter heat-up times, too. In a busy coffee shop or bar, that quick preheat can translate to happier customers and a leaner utility bill.

Seattle Bakery Case Study

Elm Street Café traded its static deck for a countertop convection unit and saw muffin bake times drop by 20%. The gains didn’t stop there:

- Trays moved directly from the under-counter fridge to the oven, cutting idle time.

- Heat spillover onto sandwich prep tables all but vanished.

- Staff spent less time rotating trays—crumb structure stayed consistent on every rack.

This simple swap smoothed service during the weekend brunch rush without adding headcount.

When To Choose Each Oven

Convection Ovens Excel When:

- You run high-volume baking on multiple racks

- Quick reheats are needed beside sandwich, coffee, bar, or pizza stations

- You need to synchronize bake and fry cycles under tight timelines

Regular Ovens Shine When:

- You craft artisan loaves that benefit from static, radiant heat

- Delicate batters require minimal air movement

- Footprint is tight and a single-tray deck suits your proofing case

Matching the oven to its station—whether that’s a pizza prep table, sandwich station, under-counter freezer, or bar area—ensures you get the most out of every bake.

Evaluating Energy Use And Capacity

Convection ovens routinely operate at 10–20°C lower temperatures. They wrap up cooking cycles 10–25% faster than conventional models.

That shift adds up in a busy kitchen. By walking through real-world calculations and capacity charts, you’ll see exactly how oven choice aligns with your throughput goals.

- Lower heat settings can shave up to 20% off utility draw per cycle

- Faster cook times free the oven for more batches

- Deck size directly impacts energy use and guest flow

Energy Savings In Practice

Imagine a Seattle restaurant running its oven 10 hours a day. A convection unit pulling 5 kW versus a conventional one at 6 kW makes a noticeable difference at $0.10 per kWh:

- Convection: 5 kW × 10 h × $0.10 = $5.00/day

- Conventional: 6 kW × 10 h × $0.10 = $6.00/day

Over 30 days, that’s:

- Convection monthly = $150

- Conventional monthly = $180

“Switching to convection cutters saved us $360 annually on a single deck,” recounts a Seattle caterer.

This simple model highlights how choosing convection over regular can edge your bottom line.

Throughput And Footprint Impact

Footprint and deck arrangement matter as much as wattage. Single-deck ovens occupy 3 ft of line space and handle 20–25 trays/day. Multi-deck units push capacity to 40–60 trays/day, though they need heftier ventilation.

| Feature | Single-Deck Oven | Multi-Deck Oven |

|---|---|---|

| Footprint | 3 ft width | 5–6 ft width |

| Tray Capacity | 2 decks, 20 trays | 4 decks, 45 trays |

| Energy Use | 5 kW per deck | 4.5 kW per deck |

| Throughput Impact | Baseline service | +50% service volume |

Tucking ovens next to sandwich tables, pizza stations, bar equipment, or under-counter refrigerators slashes transit time and smooths service flow.

Aligning Oven Size To Guest Count

Start with your peak covers. If lunch hits 150 in three hours, that’s about 5 trays per hour. A triple-deck convection oven turning out 15 trays/hour gives you a 3× buffer—perfect for last-minute surges.

Numbered Checklist For Oven Sizing

- Calculate peak trays/hour from cover count

- Match deck count to your tray output needs

- Factor in faster heat recovery with convection

- Place ovens near refrigeration, prep tables, and fry stations to cut downtime

This method wards off bottlenecks when service heats up.

Electric Versus Gas Decision Checklist

Fuel type shapes both costs and installation. Gas ovens often run 25% cheaper per cycle but demand venting and gas lines. Electrics eliminate gas hookups but might bump your electric bill in Seattle.

“Our gas convection deck cut utilities by $25 a month, but we spent $300 on vent installation,” shares a café owner.

Decision-Making Checklist

- Compare local gas vs. electric rates

- Factor in vent hood or extra electrical circuit costs

- Ensure compatibility with adjacent equipment (fryers, prep tables, bar stations)

- Review Seattle’s code requirements for gas hookups

Choosing wisely keeps your operating expenses in check.

Integrating With Core Stations

Where you put the oven can make or break your line. Nestle it beside your pizza prep for quick reheats, park it next to the sandwich station to cut down on staff footsteps, or align it with Seattle bar equipment for small bites service.

- Lower oven temps slow dough cooldown between bakes

- Shared exhaust hoods for fryers, ovens, and bar equipment trim capital costs

- Under-counter refrigerators and freezers stay cool even during high-heat cycles

Thoughtful layout—from under-counter coolers to bar fridges—turns a good kitchen into a great one.

Key Takeaways For Operators

Run your own energy-rate and capacity scenarios before choosing.

- Sync cycle times with key stations like sandwich prep, pizza, fryers, and bar equipment

- Use capacity charts to forecast your busiest shifts alongside under-counter and full-size storage

- Weigh utility rates and installation costs when picking gas or electric

Pairing careful energy planning with capacity analysis ensures your kitchen isn’t just surviving—it’s thriving.

Seattle Restaurant Equipment offers a broad range of convection and conventional ovens. Match your specs to your service patterns, and you’ll balance energy efficiency with capacity needs seamlessly.

Real World Use Cases And Recommendations

In Seattle’s busiest kitchens, choosing between a convection oven and a conventional deck can reshape how every station runs. It’s not just about bake times; it’s about syncing ovens with refrigerators, prep tables, bar stations, and fryers. Below are four real-world examples that tie oven type to layout, station flow, and output.

Pizza Shop Bake Cycle Optimization

At Mariner’s Pizza, swapping in a deck convection oven beside the pizza prep table slashed bake cycles by 20%, lining up perfectly with their dough proof times. Stacking three pies per rack didn’t create any hotspots, so throughput climbed on Friday and Saturday nights.

- Fan-driven airflow delivers even crust color on every rack

- Dough balls move straight from under-counter freezers to the oven

- Team members batch pizzas alongside sandwich prep to stop bottlenecks

“Batch baking with convection gave us a 30 percent lift in sales during peak service,” says owner Luis.

This setup also cut foot traffic and synced bake completion with Seattle Restaurant Equipment’s bar fridges.

Coffee Bar Quick Reheat Applications

In a Capitol Hill café, a countertop convection oven lives next to the espresso machine. By preheating to 175 °C during the latte rush, pastry warm-ups dropped by 15 seconds each. Now, under-counter fridges handle just milk and sandwich ingredients alongside Seattle coffee shop refrigerators.

- Heat the unit as the barista pulls the next shot

- Load three racks of croissants from the display

- Serve fresh pastries alongside coffee in under two minutes

Baristas report far fewer cold spots and a more consistent finish compared to their old static toaster.

Sandwich Shop Even Toasting Results

Deli Delights dealt with uneven slices from a standard deck oven. A switch to a fan-assisted model delivered uniform toasting—no rotating pans required. They placed their convection deck beside the fryer to handle both bread and fillings in one zone, next to their sandwich prep tables.

- Crisp edges without soggy centers

- Proteins flow directly from freezer to fryer

- Throughput rose 25% with minimal staffing tweaks

Batch Cooking Versus Artisan Baking

High-volume casseroles thrive in a multi-deck convection oven, but artisan bakeries often stick with a simple deck for hearth breads. Radiant heat on stone develops that deep caramelized crust traditionalists crave.

| Scenario | Convection Oven Advantage | Regular Oven Advantage |

|---|---|---|

| High-Volume Casseroles | Even heat across all decks | N/A |

| Artisan Sourdough Loaves | Quick preheat, lighter crust | Deeper steam retention |

| Multi-Station Service Flows | Centralized timing control | Straightforward dials |

Sequencing Equipment Layout

Pair each oven with its natural neighbor to cut handoffs:

- Convection decks next to pizza tables, fryers, and sandwich prep tables

- Static ovens near pastry cases, coffee fridges, and bar equipment

- Group sandwich stations with convection units for on-demand toasting

For more layout ideas, see our guide on used commercial kitchen equipment.

A simple decision tree helps you finalize the mix:

- List menu items by station

- Match batch sizes to bake times

- Align oven capacity with refrigeration footprint and deep fryers

- Sequence stations from cold storage to cooking

These steps drive smoother service, lower energy bills, and consistent results.

Final Recommendations And Next Steps

Map your menu to the stations it touches and run test cycles to spot delays. A compact convection deck handles high-turnover items—think reheats or bulk cookies—while a regular oven sits best by your bread or dessert display for radiant finishes.

- Pair countertop convection ovens with under-counter refrigerators to minimize steps

- Line up fryers, convection units, sandwich tables, pizza prep, and bar equipment for a continuous cook-and-fill flow

- Keep a static oven on hand for slow-bake or specialty items

Key takeaway: When oven choice, station layout, and cold storage align, you eliminate wasted steps and keep service lean.

Review your kitchen diagram, tweak placements, and test before making big equipment purchases. That hands-on approach is the fastest way to a smarter, faster line.

Maintenance Installation And Buying Guide

Installing a convection or conventional oven in a Seattle kitchen takes foresight. You’ll need to balance local codes with smooth operations, ensuring exhaust hoods, clearance zones, and utility hookups all line up perfectly. To pull this off, coordinate early with your HVAC tech, electrician, and utility provider—don’t wait until the unit shows up.

Ventilation And Clearance Requirements

Proper hood sizing isn’t optional—it’s essential for air quality and safety.

- Gas convection decks typically draw 600–900 CFM per deck.

- Electric ovens can often share a common hood when capacity allows.

- Seattle health codes require 18 inches clearance on each side and a three-foot service zone in front.

Adequate spacing protects nearby prep tables, under-counter fridges, freezers, coffee stations, and bar equipment from overheating. Talk to an HVAC pro early to nail down hood dimensions and duct routing before your oven arrives.

Correct hood sizing and clearance can lower service calls by 30% and extend oven life.

Electrical And Gas Connections

Planning power and gas lines upfront helps you dodge expensive retrofits.

- Electric models need a dedicated 208–240V, 50–60 A circuit per deck.

- Gas ovens demand a ¾-inch line, regulator, and shutoff valve within five feet.

- Always test gas pressure and voltage before installation.

- Expect conduit or piping extras to add 20–30% to your budget.

| Connection Type | Requirement | Typical Installation Cost |

|---|---|---|

| Electric | 208–240V, 50–60 A circuit | $600–$1,300 per circuit |

| Gas | ¾-inch line, regulator, shutoff valve | $350–$900 per hookup |

Routine Cleaning And Troubleshooting

A solid cleaning routine keeps ovens reliable and efficient.

- Daily: Wipe down walls and racks to stop carbon build-up in its tracks.

- Monthly: Clean baffles and blowers so fan motors run smoothly.

- Quarterly: Inspect gaskets, sensors, and elements before wear creates hot spots.

If your oven starts heating unevenly or makes odd noises, check the gasket seals and fan blades first. An infrared thermometer slips under your radar, revealing cold pockets without opening the door and losing heat.

Troubleshooting Tip: Use an infrared camera or heat gun to spot cold spots instantly.

Market Trends And Supplier Selection

Countertop and combo convection ovens are rewriting how kitchens buy and deploy equipment. The global countertop oven market hit USD 7.68 billion in 2023, with a projected 4.9% CAGR through 2030. For a deeper dive, read the Grand View Research countertop oven market report.

Seattle Restaurant Equipment stocks compact models ready to ship, backed by local setup support and warranty service. Plus, they offer free delivery across Washington—usually within 1–2 business days to Seattle, Tacoma, Bellevue, Kent, Everett, and Spokane.

Buying Criteria Checklist

Match oven specs to your kitchen’s flow by ticking off this list:

- Average and peak capacity for your covers.

- Energy rating against local kW or BTU rates.

- Footprint dimensions to fit alongside prep tables and under-counter units.

- Compatibility with refrigerators, freezers, pizza and sandwich stations, bar equipment, coffee shop refrigerators, under-counter units, and deep fryers.

- Service support and warranty terms in Washington state.

For detailed kitchen layout advice and station sequencing, check out our guide on setting up a commercial kitchen Learn more about kitchen configuration.

Parts Lifespan And Warranty Support

Every oven part has its own lifecycle under daily restaurant use:

- Fan motors last about 3–5 years.

- Heating elements run 2–4 years depending on cycles and cleaning.

- Gaskets and door seals typically need swapping every 6–12 months.

Seattle Restaurant Equipment carries OEM replacements and extended warranties to keep you covered. Their Washington-wide service network even offers next-day parts delivery for common components like thermostats and blowers—minimizing downtime when orders peak.

Expert Advice: Regularly updating gaskets and calibrating thermostats keeps ovens in top performance year-round.

With the right installation and maintenance, your ovens will run more efficiently, boost throughput, and last longer. Align them with refrigeration, prep, and fry stations to streamline every service. Thanks to local support from Seattle Restaurant Equipment, your next oven investment just got a lot easier.

FAQ

What Maintenance Steps Extend Oven Lifespan?

When you invest in a high-grade oven, a simple routine goes a long way. Wipe down spills and grease after each shift to keep door seals tight and sensors clear. Every three months, inspect gaskets and give fan motors a quick squirt of lubricant to prevent heat loss and unnecessary wear.

How Do Convection Ovens Change Staff Training Needs?

Convection cooking flips the script for your team. You’ll typically drop recipes by 25°F compared to a conventional oven, and trays need less juggling. Training focuses on airflow—line cooks learn to space pans evenly around the fan and keep an eye on performance.

Can Regular Ovens Handle Multiple Trays Without Hot Spots?

Static ovens rely on radiant heat, so running two or three racks means manual rack rotation to avoid undercooked corners. For a busy four-tray cycle, many kitchens tuck a small convection deck beside pizza or sandwich prep tables. That way, every batch comes out uniform without constant tray shuffling.

- Daily: Wipe walls, racks, and doors

- Monthly: Clean blowers and fan assemblies

- Quarterly: Inspect gaskets and sensors

Tip: Use an infrared thermometer to map hot spots in convection vs. conventional ovens.

Installation And Layout

What Installation Factors Drive Costs In Seattle?

Local regulations and labor rates can add $300–$1,300 to your buildout. Vent hood sizing, required CFM, and gas-line hookups all play a part. Plus, if your ovens sit adjacent to under-counter fridges, freezers, sandwich prep tables, bar equipment, or fryers, longer duct runs and extra clearance will bump up hours (and ticket prices).

How Do I Integrate Ovens With Refrigeration And Prep Tables?

Workflow is king in a tight kitchen. Position the oven between under-counter freezers and your sandwich or pizza table to slash walking time. Then pair that station with a nearby deep fryer or coffee-shop refrigerator. Cross-station synergy like this cuts transit time and boosts overall throughput.

For tailored advice on ovens, refrigeration, prep tables, and more, contact Seattle Restaurant Equipment.