Think of a commissary kitchen as the command center for your mobile food business. It's the licensed, professional home base where the real magic happens—all the prep, cooking, storage, and cleanup that you can't legally do in your truck or at home.

For any food truck, caterer, or ghost kitchen in Washington, using a compliant commissary isn't just a good idea; it's a non-negotiable first step to building a business that lasts.

Your Launchpad for a Legal Food Business

If you're running a food business without a traditional brick-and-mortar spot, you can't just prep food in your home kitchen. It’s illegal. Health departments are sticklers about this, and for good reason—they need to know that every meal you serve comes from a clean, safe, and regularly inspected commercial facility.

This is where the commissary comes in. It's the launchpad for your culinary dream. Your food truck might be the rocket that delivers your incredible food to the masses, but the commissary is mission control. It’s where you refuel, restock, and make sure all systems are a "go" before you hit the streets.

Core Functions of a Commissary Kitchen

A good commissary gives you all the essential infrastructure your mobile business is missing. It’s where you tackle all the behind-the-scenes work that keeps you running legally and efficiently.

Here’s what you get:

- Safe Food Preparation and Cooking: You’ll have access to commercial-grade ovens, deep fryers, and plenty of counter space to prep your ingredients without breaking a single health code.

- Secure Food Storage: Proper storage is a huge deal. This means walk-in coolers, commercial freezers, and shelving that keeps every ingredient safely off the floor.

- Sanitation and Cleaning: Access to three-compartment sinks for properly washing, rinsing, and sanitizing your gear, plus dedicated handwashing stations, is an absolute must.

- Waste Disposal: A compliant way to get rid of grease, gray water, and trash, all according to local health rules.

This shared kitchen model isn't just a niche idea; it's the backbone of the modern food industry. The global ghost kitchen market hit around $63 billion in 2023 and is on a rocket trajectory to $160 billion by 2030. That explosive growth shows just how critical these spaces are. If you want to dig deeper, TouchBistro has some great insights on the rise of commissary kitchens.

Essential Equipment for Your Commissary Base

Whether you’re choosing a commissary to rent or building one yourself, having the right equipment is everything. You need workhorse gear that can handle the daily grind. For example, commercial refrigerators and under counter freezers are designed to hold precise, food-safe temperatures in a way your fridge at home never could.

Versatile workstations like sandwich prep tables or specialized pizza prep tables can make or break your workflow. And for operators here in Seattle, having easy access to reliable Seattle bar equipment or a dedicated Seattle coffee shop refrigerator within your commissary can be a game-changer, letting you expand your menu without skipping a beat. At the end of the day, your success hinges on having the right tools at your home base.

2. Navigating Washington Health Codes and Permits

Before you even dream of sizzling bacon or stocking your first commercial freezer, you have to get a handle on the local rules of the game. Let's be clear: meeting commissary kitchen requirements in Washington isn't a simple, statewide checklist. It's a hyper-local maze of city and county regulations. What gets you a green light in Spokane might get you a hard stop in Seattle.

Why the headache? Because there’s no single national standard. Licensing and what’s expected of you, the tenant, can be wildly different between, say, King County and Pierce County.

That said, some things are non-negotiable everywhere. Every commissary has to meet rock-solid health and safety standards. This always boils down to having the right food handler certifications for your team, a business license backed by a health inspection, and proper mechanical and fire codes. For a deeper academic look at these local frameworks, the International Food Protection Training Institute has a detailed analysis worth reading.

The Landlord and Tenant Analogy

Think about your relationship with a commissary kitchen like you would an apartment lease. This simple analogy makes it crystal clear who’s responsible for what.

The commissary owner is your landlord. They're on the hook for the building's core infrastructure. That means making sure the facility has approved plumbing, working ventilation, solid pest control, and proper waste disposal. Their name is on the building's main health permit, and the buck stops with them for the facility itself.

You, the food entrepreneur, are the tenant. It's your job to keep your "apartment"—your specific prep station, your storage shelves, your time in the kitchen—clean and compliant. This covers your own food handling practices, avoiding cross-contamination, and making sure every person on your team has a valid food handler permit. You're renting a space that's already up to code, but you have to keep it that way.

Do Your Homework Before You Sign Anything

This landlord/tenant distinction is everything. Before you even think about signing a lease or membership agreement, you have to do your due diligence. Call the local health department, like Public Health – Seattle & King County, and verify the commissary's compliance status.

When you sign on, you're essentially "inheriting" their good standing. If the facility has a history of violations or isn't properly permitted, your business is dead in the water before you even start. You simply cannot get your own food business license without a signed agreement from a fully compliant, health-department-approved commissary. It's the foundational document for your entire operation.

The Key Permits and Certifications You’ll Need

Once you’ve found a great, compliant commissary, the spotlight turns to your own business's paperwork. The facility provides the stage, but you have to bring the right credentials to perform. For a deeper look at the equipment and logistical side of this, check out our guide on setting up a commercial kitchen.

Here's a quick look at the permits and licenses you, as the "tenant," will absolutely need to get sorted.

Before we dive into the list, let's organize the key requirements into a simple checklist. This table breaks down what you need, who's responsible for it, and where you'll typically go to get it.

Key Regulatory Checklist for Washington Food Businesses

| Requirement Type | What It Is | Who Is Responsible | Where to Apply (Example) |

|---|---|---|---|

| State Business License | The master license required to conduct any business in Washington. | You (The Tenant) | Washington State Dept. of Revenue |

| Local City License | A city-specific license to operate within municipal limits (e.g., Seattle, Tacoma). | You (The Tenant) | City of Seattle, City of Bellevue, etc. |

| Food Worker Card | A mandatory certification for every person who handles food. | You & Your Staff | Local Health Department (e.g., Public Health – Seattle & King County) |

| Commissary Agreement | A signed contract with a health-department-approved kitchen. | You (The Tenant) | The Commissary Kitchen Owner |

| Mobile Food Unit Permit | A specific permit for food trucks, which is tied to your commissary agreement. | You (The Tenant) | Local Health Department |

This checklist isn't exhaustive, but it covers the core documents you can't operate without. Always double-check with your local health department for any additional requirements specific to your business type.

Here’s a bit more detail on what these involve:

- State of Washington Business License: This is your starting point. You can't legally operate any business in the state without it.

- Local City Business License: On top of the state license, cities like Seattle, Bellevue, and Tacoma have their own licensing requirements. Don't skip this step.

- Food Handler Permits: This isn't optional. Every single person on your team who touches food—from the head chef to a part-time prep cook—must have a valid Washington State Food Worker Card.

- Mobile Food Unit Permit (if applicable): If you're running a food truck, this permit is directly linked to your approved commissary agreement. No commissary, no permit.

If you fail to get any one of these documents, you can't legally sell a single taco or cupcake, even if your commissary is the cleanest in the state. The health department sees the commissary and the businesses inside it as a connected ecosystem. One weak link can put the entire operation at risk.

Essential Equipment for a Compliant Kitchen

This is where the rubber meets the road. Outfitting your commissary kitchen is where all the compliance theory crashes headfirst into physical reality. We’re not just talking about buying appliances; this is about investing in the specific, commercial-grade tools that health inspectors demand and your business needs to survive.

Let's be crystal clear: using residential equipment is a complete non-starter. It’s an automatic inspection failure and, frankly, a massive safety risk.

Commercial-grade equipment is built tough for a reason—it’s designed for durability, high performance, and most importantly, food safety. Just picture a home refrigerator trying to keep up with the constant opening and closing in a busy kitchen. It can’t. The compressor is too weak, leading to temperature swings that send your food straight into the bacterial "danger zone" (40°F to 140°F).

This is exactly why a health inspector’s first move is often to look for the NSF (National Sanitation Foundation) seal on your gear. It’s the gold standard.

The Bedrock of Food Safety: Refrigeration

Your first and most critical equipment category is refrigeration. Without solid cold storage, your inventory is at risk and your business is a liability. This is the absolute cornerstone of your food safety plan and a major focus of all commissary kitchen requirements.

The real difference between commercial and residential refrigeration comes down to power and recovery time. A commercial unit has a beast of a compressor that can yank the internal temperature back to a safe level moments after the door closes, even during a chaotic rush. A home unit just can’t recover that fast, putting your food—and your customers—at risk.

The gear you choose here directly impacts whether you sink or swim. The global market for commercial kitchen appliances was valued at a staggering $98.34 billion in 2024 and is expected to hit $149.34 billion by 2030. That growth tells you everything about the importance of high-performance, compliant equipment.

For you, this means making sure every piece, like an R-290 certified refrigerator, meets strict EPA standards. You can dig deeper into the financial and regulatory aspects of kitchen equipment on this PMC article.

Key refrigeration units to have on your list:

- Commercial Refrigerators: These are the workhorses. Look for stainless steel reach-in models that are a breeze to clean and tough enough for the daily grind.

- Commercial Freezers: Crucial for long-term storage, these units have to hold a steady 0°F or below to stop spoilage and freezer burn in their tracks.

- Under Counter Refrigerators and Freezers: Perfect for tucking under prep stations to maximize your space and keep frequently used ingredients right where you need them.

If your business has specific needs, you'll need specialized refrigeration. A deli or sandwich shop will find a sandwich prep table with built-in cold wells to be a total game-changer. In the same way, pizzerias lean heavily on pizza prep tables to keep toppings organized and perfectly chilled. Even a mobile coffee cart using a commissary needs a dedicated Seattle coffee shop refrigerator to keep milk and dairy at precise, safe temperatures.

High-Performance Cooking and Preparation Gear

Once your cold storage is handled, it’s time to equip your cooking line. This is where raw ingredients become delicious, finished products, and the right equipment is what guarantees consistency, speed, and safety. Every single piece of cooking equipment has to be commercial-grade to take the heat of high-volume use and meet fire safety codes.

A high-output deep fryer is a perfect example. Commercial models are built with critical safety features like automatic shutoffs and precise temperature controls that you’ll never find on a residential unit. They’re also designed for easy cleaning and maintenance, which is key for preventing grease buildup and potential fires.

The rest of your cooking line should be chosen based on your menu and workflow. A well-designed kitchen might feature a combination of ranges, griddles, and charbroilers, all humming along under a compliant ventilation hood system.

Streamlining Workflow with Smart Prep Stations

Efficiency is king in a shared kitchen. Your prep area is the bridge between your cold storage and the hot line, and this zone needs durable, easy-to-sanitize surfaces and smart tools that keep you organized.

This is where prep tables really shine. A simple stainless steel worktable is a decent start, but specialized units can completely transform your workflow.

- Sandwich Prep Tables: These units are brilliant—they combine a refrigerated base, a cutting board work surface, and refrigerated wells up top for all your ingredients. This setup cuts down on movement, reduces the risk of cross-contamination, and makes assembly incredibly fast.

- Pizza Prep Tables: Similar to sandwich tables but designed with a wider, raised rail to hold big pizza pans. The refrigerated wells are perfect for sauces, cheeses, and toppings, keeping everything within arm's reach.

For Seattle-based businesses, having access to specialized equipment can open up whole new revenue streams. A food truck, for example, might use the commissary's Seattle bar equipment, like an underbar ice bin or glass washer, to prep for big events. That kind of versatility is a huge advantage of the commissary model.

Investing in the right equipment from day one isn't just about checking boxes to meet commissary kitchen requirements; it's about building a solid foundation for an efficient, safe, and profitable food business. Every piece, from the biggest walk-in cooler to the smallest under-counter freezer, plays a vital role. To help you build out your shopping list, make sure you use a detailed commercial kitchen equipment checklist.

Mastering Ventilation And Fire Safety

Let's talk about the two systems that are the silent, non-negotiable guardians of any commercial kitchen: ventilation and fire suppression. Forget the gleaming stainless steel for a moment. These systems aren't fancy add-ons or optional upgrades. Health departments and fire marshals live and breathe this stuff, and they will scrutinize your setup intensely.

Getting this part of your commissary kitchen requirements right is non-negotiable. It's about protecting the building, your people, and your entire business from a catastrophic fire.

Think of your kitchen's air as a busy highway. Every time you cook, you're creating traffic—a constant flow of heat, steam, smoke, and nasty, grease-filled vapors. Without a proper ventilation system, you get a toxic traffic jam. A good system is like a perfectly designed interchange, pulling all that bad air out and bringing fresh, clean air in.

This is where understanding hood types becomes absolutely critical. Every commercial kitchen needs ventilation, but the kind of hood you need depends entirely on what's cooking underneath it.

Type I vs Type II Hoods: A Critical Distinction

Not all ventilation hoods are the same, and installing the wrong one is an automatic fail during an inspection. The choice boils down to one simple thing: grease.

-

Type I Hoods (Grease Hoods): These are the heavy hitters. They are required by law over any piece of equipment that kicks out grease or smoke. We're talking ranges, griddles, charbroilers, and especially deep fryers. They have special baffle filters designed to trap airborne grease, stopping it from building up in your ductwork where it becomes a massive fire hazard.

-

Type II Hoods (Condensate Hoods): These are for your non-grease-producing equipment. Think of them as steam and heat removers. You'll see them over commercial dishwashers or ovens used just for baking bread. They’re much simpler and don't have the heavy-duty grease filters of a Type I system.

Putting a deep fryer under a Type II hood is one of the most serious code violations you can make. That system just isn't built to handle the grease, which leads to dangerous buildup and a sky-high risk of fire. For kitchens where traditional ductwork is a nightmare, a commercial ventless hood can sometimes be a solution, but you'll always need the green light from your local authorities first.

The Anatomy of Fire Suppression

Working hand-in-hand with your Type I hood is the mandatory fire suppression system. This is your kitchen's built-in firefighter, ready to spring into action in seconds. These automated systems are typically built right into the ventilation hood itself.

Nozzles are aimed directly at your high-heat cooking equipment. If a fire ever flashes up on your fryer or griddle, the system detects that intense heat and immediately blasts a fire-retardant chemical agent, killing the flames instantly and cutting off the gas or power supply.

This system is your last line of defense. The fire marshal requires it to be not just installed, but professionally inspected and certified on a regular basis, usually every six months. In an inspector's eyes, a lapsed certification is the same as having no system at all.

Skipping this maintenance isn't just a compliance headache; you're literally gambling with your livelihood. Even a small kitchen fire can cause devastating damage, shut you down for months, and cost you a fortune. Making sure your ventilation and fire safety systems are professionally installed and meticulously maintained is one of the most important investments you'll ever make.

Getting Storage and Sanitation Right

Let’s talk about the parts of your kitchen that don’t get the glory of the hot line but will absolutely make or break your health inspection: storage and sanitation. These areas are under a microscope when an inspector walks in. For them, a box on the floor or a poorly stocked handwashing sink isn't a small mistake—it's a bright red flag.

Getting these details right from day one is non-negotiable. Think of it this way: your cooking wins over the customers, but your storage and sanitation practices are what keep the health department happy and your doors open.

The Six-Inch Rule: More Than Just a Number

One of the first things any new kitchen operator learns is the "six inches off the floor" rule. This isn't just some arbitrary measurement; it's a critical defense line against pests and contamination. When a 50-pound sack of flour or a case of tomatoes sits directly on the floor, it creates the perfect dark, undisturbed hideout for pests and makes it impossible to clean underneath.

To get this right, you need proper commercial-grade shelving. Forget the plastic racks from the hardware store. Health codes demand shelving made from smooth, non-porous materials like stainless steel or coated wire because they're a breeze to wipe down and sanitize. This setup also lets air circulate around your products and gives you clear access to sweep and mop, leaving nowhere for pests to hide.

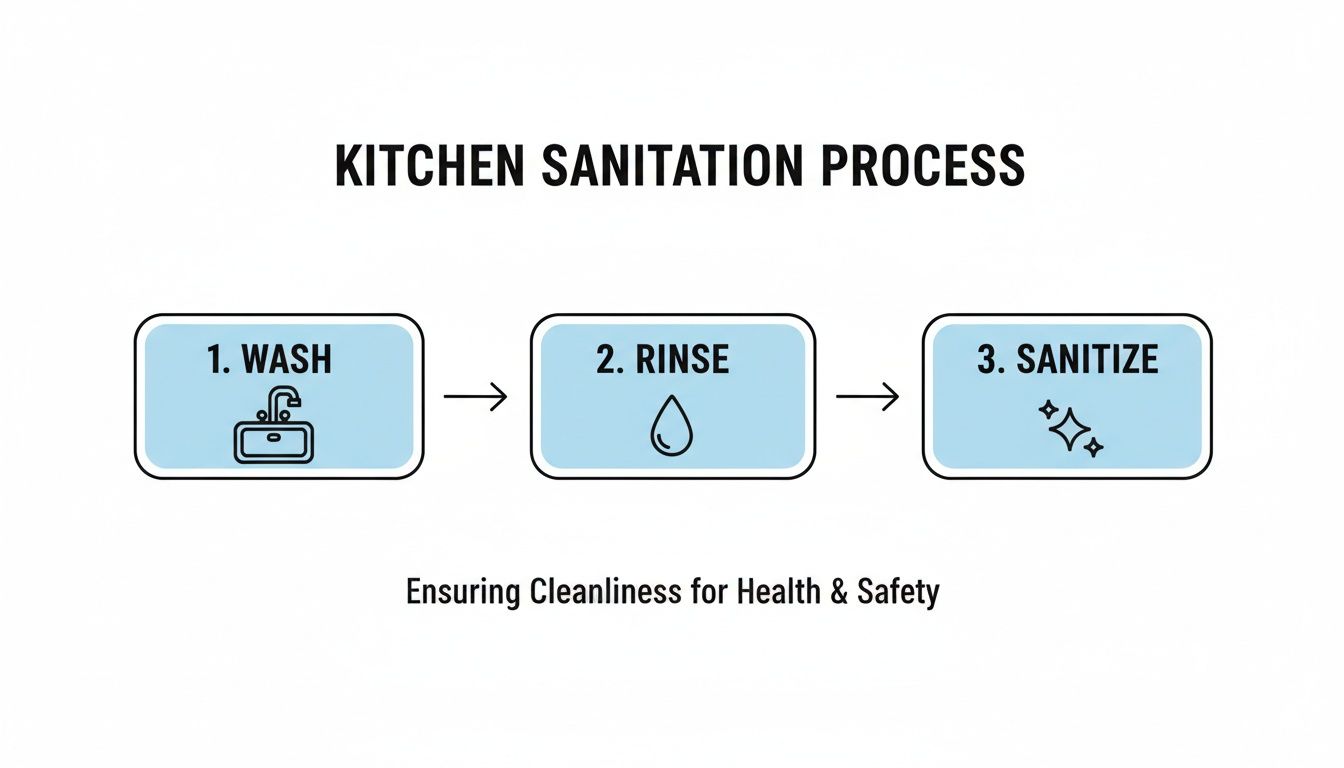

Mastering the Three-Compartment Sink

The three-compartment sink is the heart and soul of your cleaning operation. It’s not just a big sink; it's a system designed for a specific, step-by-step process that an inspector will expect you and your team to know by heart.

The flow is always the same, no exceptions:

- Wash: The first basin is for hot, soapy water. This is where you scrub off all the grease and food bits.

- Rinse: The second basin is for clean, hot water to rinse away every last soap bubble.

- Sanitize: The third basin holds your chemical sanitizer solution (or scalding hot water, depending on your setup). Items must be fully submerged for the required time to kill off any lingering bacteria.

And one more thing—everything must be air-dried. Grabbing a towel to dry a pot is a classic rookie mistake that can reintroduce germs and earn you a violation.

Why You Need So Many Sinks and Drains

Cross-contamination is one of the biggest food safety nightmares, and dedicated sinks are the primary way to prevent it.

You absolutely must have a separate handwashing sink used only for washing hands. It needs hot and cold water, soap, and paper towels, and it has to be easily accessible. If an inspector sees someone rinsing vegetables or washing their hands in a prep sink, it’s an instant, serious write-up.

Proper drainage is just as critical. Your facility needs a grease trap (also called an interceptor) to catch all the fats, oils, and grease from your sinks before they wreak havoc on the city's sewer lines. You'll also need floor drains in key areas like the dish pit and prep stations. They prevent water from pooling, which is both a slip hazard and a breeding ground for bacteria. These systems aren't glamorous, but they are essential for a clean, safe, and fully compliant kitchen.

To help you visualize what you'll need, here's a quick guide to the essential equipment for each part of your commissary kitchen, all of which you can find at Seattle Restaurant Equipment.

Essential Equipment for Commissary Kitchen Zones

| Kitchen Zone | Required Equipment Examples | Purpose/Requirement |

|---|---|---|

| Storage | Stainless Steel/Coated Wire Shelving, Dunnage Racks | Keeps all food products and supplies at least 6 inches off the floor to prevent contamination and allow for easy cleaning. |

| Sanitation | Three-Compartment Sink, Commercial Dishwasher, Handwashing Sinks | Provides the required setup for washing, rinsing, and sanitizing all cookware and a separate station for staff hygiene. |

| Hot Line | Commercial Ranges, Griddles, Fryers, Type 1 Hood Vent | The core cooking area, which must have proper ventilation and fire suppression systems installed. |

| Cold Holding | Commercial Refrigerators, Freezers, Walk-in Coolers | Maintains Temperature Control for Safety (TCS) foods at or below 41°F to prevent bacterial growth. |

| Food Prep | Stainless Steel Prep Tables, Food Prep Sink | Provides a non-porous, easily sanitized surface for preparing ingredients, separate from hand or dishwashing sinks. |

Equipping these zones correctly isn't just about having the right gear; it's about building a foundation for a safe, efficient, and profitable food business.

Designing a Smart And Compliant Layout

A smart kitchen layout is about so much more than just making your prep time faster. It's one of the most critical parts of meeting commissary kitchen requirements and, more importantly, preventing dangerous cross-contamination. Thinking about your kitchen's workflow isn't just an operational choice; it’s a fundamental safety measure that every health inspector is trained to spot immediately.

The goal here is to map out a logical "kitchen flow." You need to trace the path of your ingredients from the second they're dropped off at the receiving door to the moment they head out as a finished, packaged meal. This path should be a one-way street, making it impossible for raw ingredients to ever cross paths with cooked foods.

Creating Distinct Work Zones

A well-designed layout is built around distinct zones for each specific task. This separation is your best defense against foodborne illness. For example, the area where you prep raw chicken absolutely must be physically separate from the station where you’re chopping fresh vegetables for a ready-to-eat salad.

Your layout also has to account for where you place essential equipment. A sandwich prep table should be set up to create a smooth assembly line, letting your team pull ingredients from nearby commercial refrigerators and move the finished sandwiches toward the packaging station without backtracking. The same logic applies to a pizza prep table—it should act as the bridge between your cold storage and the ovens.

Think of your kitchen layout as a roadmap for food safety. Every station, from prep to cooking to sanitation, is a designated stop. A clear, logical path ensures there are no accidental detours that could lead to contamination.

Another non-negotiable is placing handwashing stations strategically within each zone. An inspector will check to see that your staff can wash their hands without walking across the entire kitchen, especially after handling raw meat or switching from one task to another.

Equipment Placement and Workflow

How you arrange your equipment has a direct impact on both your compliance and your team's efficiency. Under counter refrigerators and under counter freezers, for instance, should be tucked directly beneath prep stations. This keeps ingredients within arm's reach, maintains safe temperatures, and minimizes wasted steps.

High-heat equipment like deep fryers needs adequate clearance on all sides—not just for fire safety, but also to give your team room for the thorough daily cleaning that’s required.

For Seattle-based businesses, this might also mean carving out space for specialized gear. A coffee cart concept will need a dedicated area with its Seattle coffee shop refrigerator and grinders. A pop-up bar will need its own designated spot for Seattle bar equipment, kept well away from the main food prep lines.

This simple infographic nails the three-step sanitation process that anchors any compliant kitchen's cleaning station.

This visual drives home the point that washing, rinsing, and sanitizing are three separate, sequential steps. You can't skip them or mix up the order. A smart layout makes sure this station is easy to get to but doesn't interfere with the flow of food prep, reinforcing that critical separation between dirty and clean.

Got Questions About Commissary Kitchens?

Diving into the world of commissary kitchens can feel a bit overwhelming, especially when you're just starting out. It's totally normal to have a ton of questions. Let's walk through some of the most common ones and get you some clear, straightforward answers.

Can I Just Use My Home Kitchen as a Commissary in Washington?

Simply put, no. Washington state law is very clear on this: if you're a licensed food business, you have to operate out of a commercial kitchen. It's not just a suggestion; it's a legal requirement.

Your home kitchen, no matter how clean or well-equipped, just isn't built to meet the state's health code standards. Commercial kitchens have specific, non-negotiable requirements like commercial-grade equipment, specialized plumbing setups, and non-porous surfaces that are essential for food safety.

What's the First Thing a Health Inspector Looks At?

While inspectors look at everything, they have a few "make or break" items they head for first. Think of these as the critical food safety checkpoints.

Right off the bat, they will check the temperatures in your commercial refrigerators, commercial freezers, and any sandwich prep tables. They'll also immediately verify that your three-compartment sink is set up and used correctly, and that you have dedicated handwashing stations that are easy to get to and fully stocked.

Does the Health Department Really Need to See My Commissary Agreement?

Yes, they absolutely do. When you apply for your food business permit—whether it's for a food truck, a catering business, or a ghost kitchen concept—you must hand over a signed commissary agreement.

This piece of paper is your legal proof that you have access to a licensed, inspected facility for all your prep, cooking, and cleaning. Without it, you can't legally operate your business in Washington. It's that simple.

Your signed commissary agreement is the foundational document that links your mobile business to a compliant, physical kitchen. It's the key that unlocks your permit to operate. Without it, you’re just a cook with a great idea but no legal way to sell your food.

What Equipment is Absolutely Essential?

Beyond the big-ticket items, your must-have list needs to include certified refrigeration and sanitation gear. This means investing in reliable under counter refrigerators and under counter freezers is a smart move, especially for maximizing tight spaces.

Depending on your menu, you might need a high-quality deep fryer or more specialized gear like pizza prep tables. And if you’re serving drinks, things like Seattle bar equipment or a specific Seattle coffee shop refrigerator aren't just nice to have—they're often required to meet health codes.

Whether you’re launching a food truck, upgrading a busy kitchen line, or just adding some much-needed cold storage, Seattle Restaurant Equipment has the durable, commercial-grade gear you need to check every box and build a successful business. Find everything you need to equip your kitchen today.