Picking the right mop sink size is one of those foundational decisions for a smooth, clean, and compliant kitchen. The industry workhorse is typically a 24x24 inch model, but your operation might do just fine with a compact 20x20 inch unit or need a heavy-duty 36x36 inch basin.

Your Quick Guide to Mop Sink Sizes

Think of your mop sink as a crucial piece of infrastructure, not just a tub on the floor. It's the designated spot for all the heavy-duty cleaning, making sure dirty mop water stays far away from your food prep stations. For any Seattle foodservice business, this isn't just a suggestion—it's a non-negotiable part of your sanitation plan.

Getting the size right directly impacts how your kitchen flows. If the sink is too small for your standard mop bucket, your team will constantly struggle, creating spills and wasting precious time. But if you go too big for a small café, you're sacrificing valuable real estate that could be used for other essential equipment, like an extra under counter refrigerator or freezer. The goal is to hit that sweet spot from the get-go.

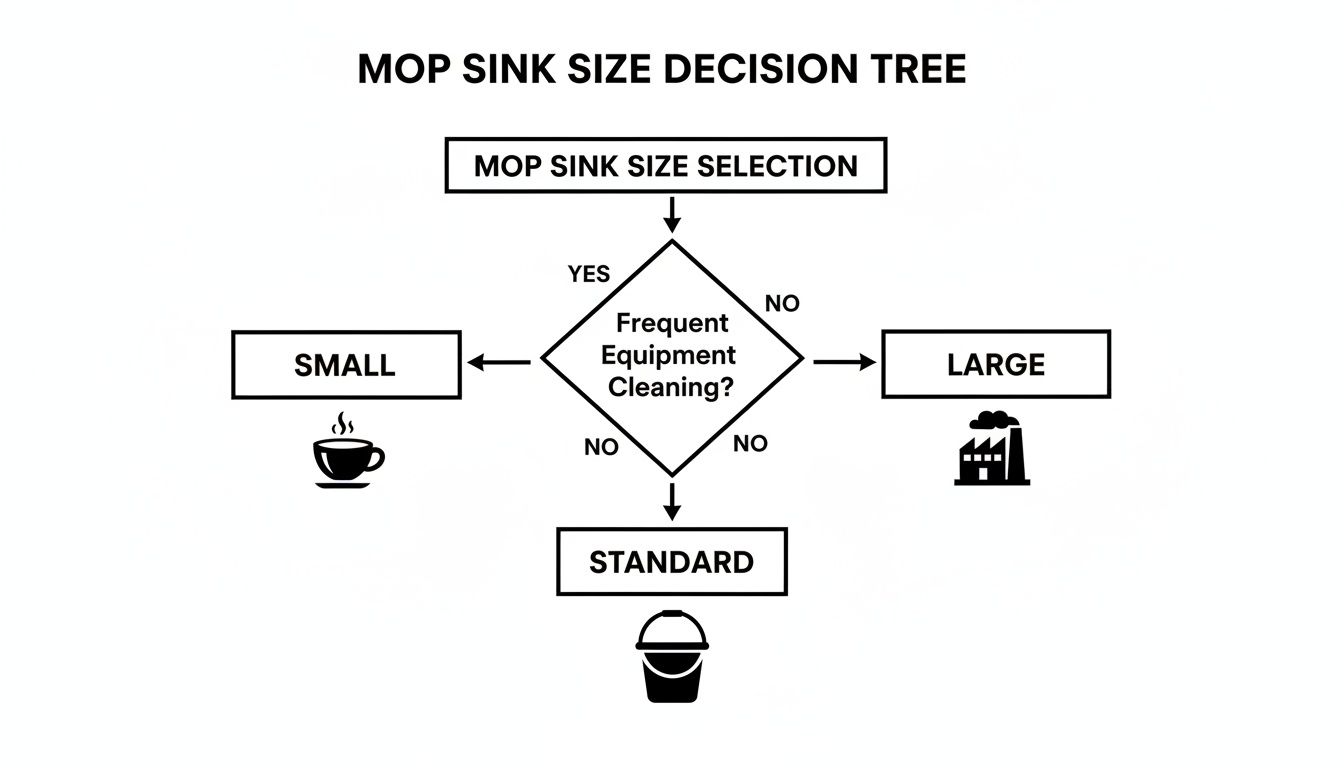

This little decision tree can help you figure out which category you fall into based on your daily cleaning needs.

As you can see, the size you need is directly tied to how much you're cleaning and the scale of your operation. To make it even simpler, we've broken it down in the table below.

Quick Reference Guide to Mop Sink Sizes

This table gives you a straightforward summary, matching common mop sink dimensions to specific types of businesses. Use it as your starting point before you get into the nitty-gritty of materials and installation.

| Size (Inches) | Ideal Business Type | Key Benefit | Common Installation |

|---|---|---|---|

| 20x20 | Food Trucks, Small Cafés, Kiosks | Space-saving, fits tight layouts | Corner, under-counter adjacent |

| 24x24 | Small to Mid-Sized Restaurants | Industry standard, balances size & utility | Floor-mounted, dedicated alcove |

| 30x30 | Large Restaurants, Ghost Kitchens | Handles large buckets & multiple users | Floor-mounted with high splash guards |

| 36x36 | Hotels, Hospitals, Commissaries | Maximum capacity for heavy-duty cleaning | Freestanding, utility room |

This is a fundamental first step. For a bigger-picture look at how everything comes together, our guide on setting up a commercial kitchen shows you how every piece of the puzzle fits.

The goal is to find the sweet spot: a sink large enough for easy bucket filling and dumping but compact enough to preserve your kitchen's layout. A well-chosen mop sink streamlines cleaning, supports health code compliance, and contributes to a smoother back-of-house operation.

Getting to Grips with Standard Mop Sink Dimensions and Features

Picking the right mop sink isn't just about finding one that fits in your janitor's closet. You've got to understand its basic anatomy, because every dimension plays a role in your daily workflow, safety, and how efficiently you can clean. All these parts work together to create a functional sanitation station.

The most common size you'll see out in the wild is the 24x24 inch model. This isn't just a random number; it’s the industry’s go-to for a reason. It’s perfectly sized to handle a standard 5-gallon mop bucket with enough wiggle room to prevent spills when you're dumping dirty water. But that external footprint is only the beginning of the story.

Key Dimensions Beyond the Basics

Three other measurements are absolutely critical for day-to-day use:

- Basin Depth: These usually run from 6 to 12 inches deep. The depth is what keeps dirty water from splashing all over your floors and walls. A deeper basin is your best friend for maintaining a hygienic space.

- Splash Guards: Look for models with high backsplashes and side splashes already built-in. Think of them as a protective barrier that gives you an extra layer of defense against messy overflows from a full bucket.

- Faucet Clearance: You need enough height between the faucet and the sink basin to actually fit a big bucket underneath. That’s why you almost always see wall-mounted service faucets—they provide the clearance and rugged durability a commercial kitchen demands.

Think of these dimensions as a system. The width and length give your bucket a landing zone, the depth handles the splash, and the faucet clearance makes filling up a breeze. If one part isn't right, the whole process gets clunky.

Floor-Mounted vs. Wall-Mounted Designs

You also have to choose how the sink is installed. Each style has its own pros and cons, making them better suited for different spaces and needs.

Floor-mounted mop sinks are the classic, most durable choice. They sit right on the floor (or are even recessed into it), which gives them unbeatable stability for constant, heavy use. The installation is a bit more involved, but their low profile makes lifting and dumping heavy water buckets much easier on your staff's backs.

On the other hand, wall-mounted (or wall-hung) sinks are elevated off the ground. Their big advantage is that you can easily clean the floor underneath them, which is a huge plus for sanitation. The trade-off is that they need a really solid wall to support them and might not be the best pick for dealing with the impact of very large, sloshing buckets.

Mop sinks are a small but vital piece of the commercial sink sector, which was valued at $915.7 million in 2025 and is expected to climb to $1,686.9 million by 2035. You can dig into more data on the growing commercial sink market to see where the industry is headed.

Matching Mop Sink Size to Your Business Needs

Choosing the right mop sink isn't just about plumbing—it's about matching the tool to the job. Think of it like a chef choosing a knife; you wouldn't use a giant cleaver for delicate garnish work. The right fit makes your whole cleaning process smoother, saves valuable floor space, and helps your team work efficiently.

A tiny coffee shop has completely different needs than a massive restaurant kitchen. By looking at a few real-world examples, you can get a much better feel for how different sizes work in different spaces, helping you invest in equipment that actually supports your business.

Small-Scale Operations: The Compact Solution

For businesses where every single square inch is prime real estate, a smaller mop sink is a smart move. Think about a cozy Seattle coffee shop or a bustling food truck. The floor plan is already packed with essentials like Seattle coffee shop refrigerators and a couple of under counter freezers. Wasting that space on a bulky utility sink just doesn't make sense.

In this kind of setup, a 20x20 inch mop sink is the perfect fit. Its small footprint lets you tuck it into a corner, leaving more room for storage or another piece of equipment that makes you money. It’s still big enough for your daily cleaning without getting in the way of the workflow around your under counter refrigerators.

Mid-Sized Restaurants: The Industry Standard

Now, let's picture a busy, full-service restaurant. The cleaning demands are constant, from mopping the dining room every night to hosing down kitchen mats. The back-of-house is a fast-paced environment with staff moving between commercial refrigerators, sandwich prep tables, and hot deep fryers.

This is where the classic 24x24 inch mop sink really proves its worth. It strikes the perfect balance, offering enough capacity for a standard 5-gallon mop bucket without splashing dirty water everywhere and creating a slip hazard. This size is the dependable workhorse of the industry, supporting a heavy cleaning schedule while fitting right into the flow of a standard commercial kitchen.

At its core, picking a mop sink size comes down to two things: how much cleaning you do and how much space you have. It’s a simple calculation that balances your daily workload against the layout of your kitchen and the placement of critical Seattle Restaurant Equipment.

Large-Volume Facilities: The Heavy-Duty Choice

Finally, imagine a large hotel, a sprawling commissary kitchen, or a popular brewery with lots of specialized Seattle bar equipment. These places have huge floors and face non-stop, heavy-duty cleaning challenges. The janitorial team might be cleaning several big areas at once, needing a central station that can handle high volume without causing a traffic jam.

For these operations, a big 36x36 inch basin is a necessity. This powerhouse can handle multiple buckets at once, accommodate large cleaning tools, and take the abuse of a high-traffic environment. It makes sure the cleaning process is just as streamlined as the production line, where crews are working around massive commercial freezers and long pizza prep tables. In a large-scale operation, going too small on the mop sink would slow everything down and compromise your sanitation standards.

Don't Forget the Plumbing and Health Codes

Picking out the right size mop sink is just the start. The real make-or-break part of the installation is making sure it lines up perfectly with all the local plumbing and health codes. You have to think of your mop sink as more than just a tub; it’s a self-contained ‘cleanup station’ that has its own set of rules to keep your whole kitchen safe and sanitary. Trying to cut corners here isn't an option—it’s a fast track to failed inspections, hefty fines, and major operational headaches.

The number one rule behind all these regulations is preventing cross-contamination. Health codes are non-negotiable on this point: dirty mop water from cleaning floors has to stay completely separate from any area where food is handled. That’s exactly why a dedicated service sink is required by law. It keeps the grime far away from your sandwich prep tables or pizza prep tables. It’s a simple concept, but it's the bedrock of a sanitary kitchen.

The Code Essentials You Can't Ignore

To get your installation right from the very beginning, a few key plumbing components are mandated by codes like the International Plumbing Code (IPC). These aren't just good ideas; they're absolute requirements for a safe setup.

- Drain Size Matters: Most health departments will require a 3-inch drain for a mop sink. Anything smaller is just asking for trouble, as it can easily get clogged with dirt and debris, leading to nasty backups.

- A P-Trap is a Must: That U-shaped pipe under the sink is called a P-trap. It holds a small amount of water to create a seal, which stops gross sewer gases from creeping up into your kitchen. It’s absolutely essential for both safety and keeping foul odors at bay.

- Backflow Prevention is Critical: A backflow prevention device, which is often built right into the faucet, is another non-negotiable piece. It ensures that contaminated water can't get sucked back into your clean water lines, which is a massive public health risk.

These parts are just as vital as the systems you have for your other kitchen equipment. For a closer look at managing all that kitchen wastewater, check out our guide on grease trap sizing.

Getting the Nod from the Health Inspector

While the IPC sets the general rules, your local health inspector is the one who has the final say. They're going to check that your mop sink is installed correctly and, just as importantly, that it's only being used for janitorial work. That principle of separation is everything—your mop sink area needs to be clearly distinct from any station where food is being washed or prepped.

A properly installed mop sink is your first line of defense against cross-contamination. When you follow the codes for drain size, P-traps, and backflow prevention, you're building a system that protects your staff, your customers, and your reputation.

This intense focus on hygiene is a huge factor in the global sink market, which was valued at a whopping $7.92 billion in 2024. Interestingly, single-bowl sinks—the category most mop sinks fall into—made up 48.24% of those sales. They're a popular choice for commercial spots where every square inch counts and sanitation is king. You can see more details about the expansive sink market on marketdataforecast.com. The best advice? Work closely with your plumber and have a chat with your local health department before you start. That way, you'll know every little detail is covered long before you open for business.

Installation Planning: Beyond the Basics

Alright, you've picked out the perfect mop sink. That's a great start, but now comes the real puzzle: where to put it and how to install it. Getting this wrong can throw a wrench in your whole back-of-house operation, creating annoying bottlenecks and even safety risks. The goal here is to carve out a utility space that's not just functional but also smart, giving your crew the elbow room they need to work safely and efficiently.

Think of the floor around your mop sink like a busy intersection. Your staff has to be able to roll a full, sloshing mop bucket right up to the basin without doing a clumsy shuffle. A good rule of thumb is to leave at least 24-36 inches of clear floor space right in front of the sink. This gives everyone enough room to move without tripping and makes routine maintenance a breeze.

Having functional, hygienic spaces like this is becoming more and more important. The global market for mop sinks, a small but vital piece of the commercial kitchen puzzle, was valued around $500 million in 2025. It's projected to climb to $800 million by 2033, which is a solid growth rate of 6%. This just shows how much the industry is focusing on proper sanitation setups. You can dig deeper into these numbers over at archivemarketresearch.com.

Accounting for Structural Needs

You can’t just drop a mop sink anywhere. The building itself has to be ready for it, and different sinks have different needs.

- Floor-Mounted Sinks: These big guys often need a recessed spot in your concrete floor or a raised curb built around them. This is to keep water from splashing everywhere. It’s a real construction job, so you’ll need to plan it out with your contractor from the start.

- Wall-Hung Sinks: These are great for saving floor space, but they're heavy—especially when full of water. You absolutely must anchor them to a reinforced wall with solid blocking behind the drywall. Standard drywall just won't cut it.

A well-planned utility area is more than just a place to fill a bucket. It supports the rhythm of your entire kitchen. When you think about clearance, workflow, and how the sink is installed, you create a space where cleaning gets done right, not just squeezed in as an afterthought.

Strategic Placement for Optimal Workflow

Where you install your mop sink matters just as much as which one you buy. It needs to be easy to get to but out of the way of the kitchen's main action. For instance, putting it too close to your deep fryers is a bad idea; you'll create steam and a slippery mess in an already dangerous spot.

The best place is usually a dedicated utility closet or a quiet corner of the kitchen. This keeps cleaning tasks separate from your food prep areas where you have your commercial refrigerators and pizza prep tables. This kind of smart positioning makes for a safer, more organized back-of-house, which is a big part of what we cover in our guide on restaurant kitchen layout and design. A logical layout ensures your janitorial work never trips up your culinary team.

Common Questions About Mop Sink Size and Installation

Even with a perfect plan laid out, questions always come up when you're installing new equipment. A mop sink seems simple enough, but a few common hang-ups can stop a project in its tracks or lead to a costly mistake down the road. Getting straight answers helps you move forward with confidence, making sure your utility space is compliant and functional from the start.

We've pulled together the questions we hear most often from business owners about mop sink size and installation. These answers get right to the point, tackling the real-world challenges you're likely to face when setting up your sanitation area.

Can I Just Use a Regular Utility Sink Instead?

It might seem like a clever way to save space or money, but using a standard utility sink is almost always a direct violation of local health codes. Most health departments require a dedicated service or mop sink just for getting rid of dirty water and cleaning chemicals. This rule is all about preventing cross-contamination with food prep areas or handwashing sinks.

A mop sink is built for the job. It has a deep basin, sits low to the ground for easy bucket dumping, and is made of tough materials that can handle constant, heavy use. Trying to get by with a regular sink not only puts you at risk for fines and failed inspections, but it also creates an unhygienic workspace. It's one corner you just can't afford to cut.

What Is the Biggest Mistake When Choosing a Mop Sink Size?

The most common mistake by far is underestimating the actual space needed around the sink. Too many owners get hyper-focused on the sink's footprint and try to squeeze it into the tightest corner possible. They forget that a person needs room to safely lift and dump a full, heavy mop bucket.

This isn't just an inconvenience—it leads to spills, back strain for your employees, and a daily workflow bottleneck. A good rule of thumb is to plan for at least 18 to 24 inches of clear floor space on the main access side. This ensures your staff can use it safely and efficiently.

Do Floor-Mounted Mop Sinks Require a Curb?

Yes, for most commercial setups, a curb is a must-have. Floor-mounted mop sinks are usually installed in one of two ways: they're either recessed right into the floor slab or, more often, they're surrounded by a raised concrete curb.

This curb does two very important things. First, it contains any splashes and potential overflows, which prevents water damage and dangerous slip-and-fall hazards in your back-of-house. Second, it acts as a protective barrier for the sink itself. Plumbing codes typically mandate this feature to keep your utility area safe and sanitary.

What Is the Best Faucet for a Commercial Mop Sink?

Your best bet is a heavy-duty, wall-mounted service sink faucet. Try to find one that comes with a support brace for extra stability, because these things take a beating. You’ll also want a model with a long, swinging spout that can easily fill up big buckets and reach every corner of the basin.

For durability, look for a faucet with solid brass construction and simple lever or cross handles that are easy to turn even with wet hands. One small feature that makes a huge difference is a threaded spout tip with a built-in pail hook. This lets you attach a hose and hang a bucket for hands-free filling, which really speeds things up during a busy shift.

Whether you're outfitting a new Seattle coffee shop or upgrading a high-volume restaurant, getting the details right is key. For a complete selection of reliable, commercial-grade equipment, from commercial refrigerators and freezers to sandwich prep tables and deep fryers, Seattle Restaurant Equipment has you covered. Explore our inventory and find the perfect solutions for your kitchen at https://seattlerestaurantequipment.com.